Transportation Conveyors

Unlike accumulation conveyors, which offer product transportation and accumulation, transportation conveyors are not made to accumulate products. There are three different types of transportation conveyors to choose from. Your operation type plays a large role in which will be best choice.

REB Storage Systems International is a material handling systems integrator that provides full project management of transportation conveyor systems. Our services include design, permitting support, subcontractor management, procurement of materials, and installation.

Read below to learn more about REB’s transportation conveyor systems.

REB’s Turnkey Services for Transportation Conveyor Systems

REB provides full project management of your transportation conveyor system. A REB project manager will be your point of contact throughout the project. Our project managers prioritize communication and will make sure that all applicable parties have a firm understanding of timelines and progression of the project.

Read below to better understand our transportation conveyor system project management services.

Design Services

Your REB account executive will speak with you to make sure we thoroughly understand the scope of your project. If necessary, we’ll conduct an onsite assessment. We want to make sure we understand your goals and current pain points so that we provide you with a solution that is optimized to your operation.

Submit Your Inquiry

During the design process, we’ll obtain information such as your SKU profiles, space restrictions, and picking processes. This will help us understand which type, or types, of conveyors will suit your requirements. For example, if you need to transport products to multiple pick locations, a sortation conveyor will be most helpful for expediting your picking process.

Once all information is obtained, REB project designers will create a CADD drawing of your transportation conveyor system that suits all space and picking process requirements.

Permitting Support

If necessary, we’ll evaluate if permitting for your transportation conveyor system is required. If permits are required, we’ll put together and submit all drawings and other documentation needed for permit approval. This often includes a high pile storage report.

Subcontractor Management

Once your transportation conveyor system design is finalized, your REB project manager will secure all suppliers and subcontractors. We’ll manage their involvement through the project. This includes freight and installation.

Our project managers prioritize communication and will make sure that all applicable parties have a firm understanding of timelines and progression of the project.

System Installation

REB Storage Systems has more than 60 years of professional experience installing transportation conveyor systems in warehouses nationwide. We’ll ensure that your operation’s transportation conveyor system is safely installed and compliant with MHI & OSHA standards while it optimizes your storage space and improves efficiency.

How Transportation Conveyors Work

Transportation conveyors move loads from point A to point B throughout the distribution center. Product located on pallets and cartons are typically what transportation conveyors are built to move.

These conveyors can be used for a variety of applications. This includes lightweight items that vary in size to heavier full-pallet loads. Transportation conveyor options are available to accommodate requirements such as desired speed and product handling procedures.

Transportation conveyors are one of the most common conveyor types, making it a great option for many different kinds of distribution centers. Continue reading to learn more information on transportation conveyors.

Advantages of a Transportation Conveyor

Transportation conveyors offer a variety of advantages, some of the top benefits include:

Lower initial investment.

Transportation conveyors tend to be a lower investment than other conveyor types.

Can move loads of varying sizes and weights.

This is beneficial for operations that require the transport of multiple different items at once.

Belt Speed Control.

Operators are able to control how fast or slow the belt moves. This can be beneficial for picking items as needed.

Increased space utilization.

Transportation conveyors can be set up at different heights throughout the warehouse to maximize space.

Types of Transportation Conveyors

If you are interested in implementing a transportation conveyor into your warehouse, consider the three different types that are available.

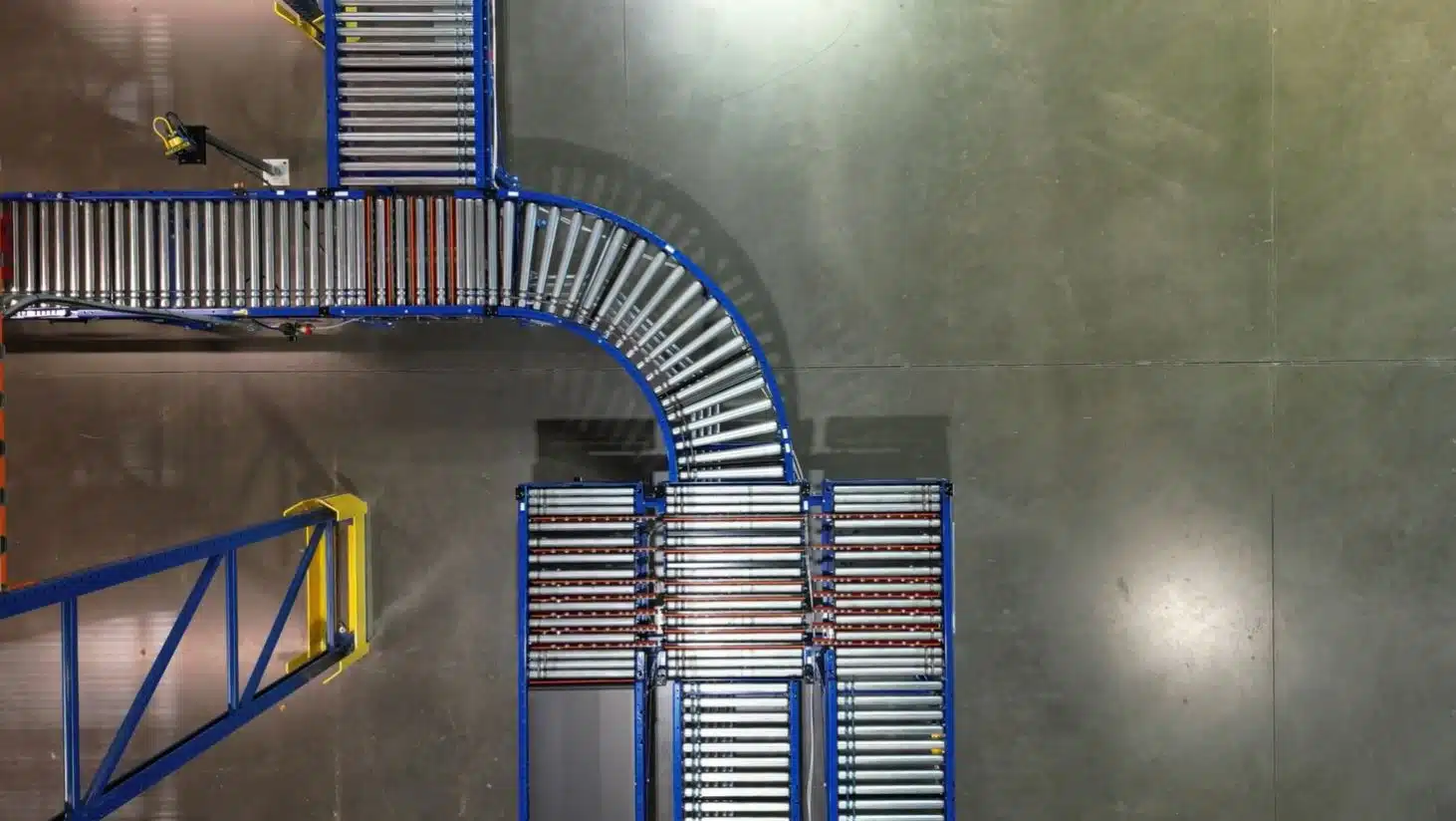

Live Roller Conveyors

Live roller conveyors are a common type of transportation conveyor. There are two different types of live roller conveyors, belt-driven and chain-driven. They are ideal for a number of applications and can suit just about any warehouse operation type.

How It Works

Live roller transportation conveyors push loads by applying power to either some or all of the rollers. There are options available for light duty to heavy duty requirements, with rollers increasing in size for heavier applications.

Ideal Uses

While live roller conveyor can be used in many applications, some ideal applications are:

- Transporting of stable, firm loads.

- Common applications include cartons, skids, drums, and bagged items.

Belt-Driven Live Rollers

Belt-driven live roller conveyors utilize a flat, round, or v-belt with rollers on top. Unlike standard belt conveyors, belt-driven live roller conveyors are not recommended for transporting items to various levels.

Chain-Driven Live Rollers

Chain-driven live roller conveyors utilizes chains to drive sprockets on the rollers. The properties of the chain and rollers allows this type of conveyor to be used in a wide variety of applications not suited for belt conveyors. This includes hot and cold loads, loads that contain grease, and uneven loads.

Belt Conveyors

Belt conveyors are a good option to transport product at a high speed. They are capable of carrying various sized loads for long distances. They are one of the most commonly used conveyor types.

How It Works

Belt transportation conveyors use a wide belt and pulleys that are supported by rollers or a flat pan along its path. High friction between the belt and the item allows these conveyors to move materials at a set speed on an incline or decline, making it a viable option for facilities that require transport of items to various levels.

Ideal Uses

Belt conveyors are a good option for operations that:

- Transport product in bulk.

- Are interested in small parts inventory handling.

Gravity Conveyors

Gravity conveyors are the least expensive transportation conveyor option. This is because it does not need electricity to function. Although it has the lowest investment, gravity conveyors have the lowest ability of control over the flow of product.

How It Works

Gravity conveyors do not utilize power, instead they are pitched so that gravity is able to move product from one point to the next. They can be straight, curved, or spiral and are made up of a frame and rollers or wheels that help guide the product from point A to point B.

Ideal Uses

The ideal applications for gravity conveyors are:

- Staging in order fulfillment areas.

- Truck off-loading.

- Assembly areas.

Your Next Steps For a Transportation Conveyor

Now that you have a better understanding of transportation conveyors, please consider contacting a REB professional today. Whether you are certain which type of transportation conveyor is right for you, or if you need more guidance, REB experts are here to help.

REB is a highly experienced systems integrator, in business since 1962. REB currently has 17 in-house project managers and project designers, all highly experienced in the material handling industry. These professionals know this industry inside and out.

We’d appreciate the opportunity to help you further, whether that be more information or a quote. Fill in the contact form on this page or call us at (800) 252-5955 to get in touch with a REB representative.