Articles & White Papers

Cold Storage Racking 101: Pick the Right Cold Storage Racks

Coolers and freezers present unique storage challenges. Because of cold temperatures and limited space, using the right type of racking can make or break your operation (literally). Read to understand which types of racking is right for your cooler or freezer.

When to Use Last-in, First-out Storage (LIFO)

Last-in, first-out (LIFO) is a type of inventory management that allows inventory placed into a rack system last to be removed first. Last-in, first-out storage is most often used for goods with a long shelf life or those held in large quantities.

Warehouse Product Flow Options

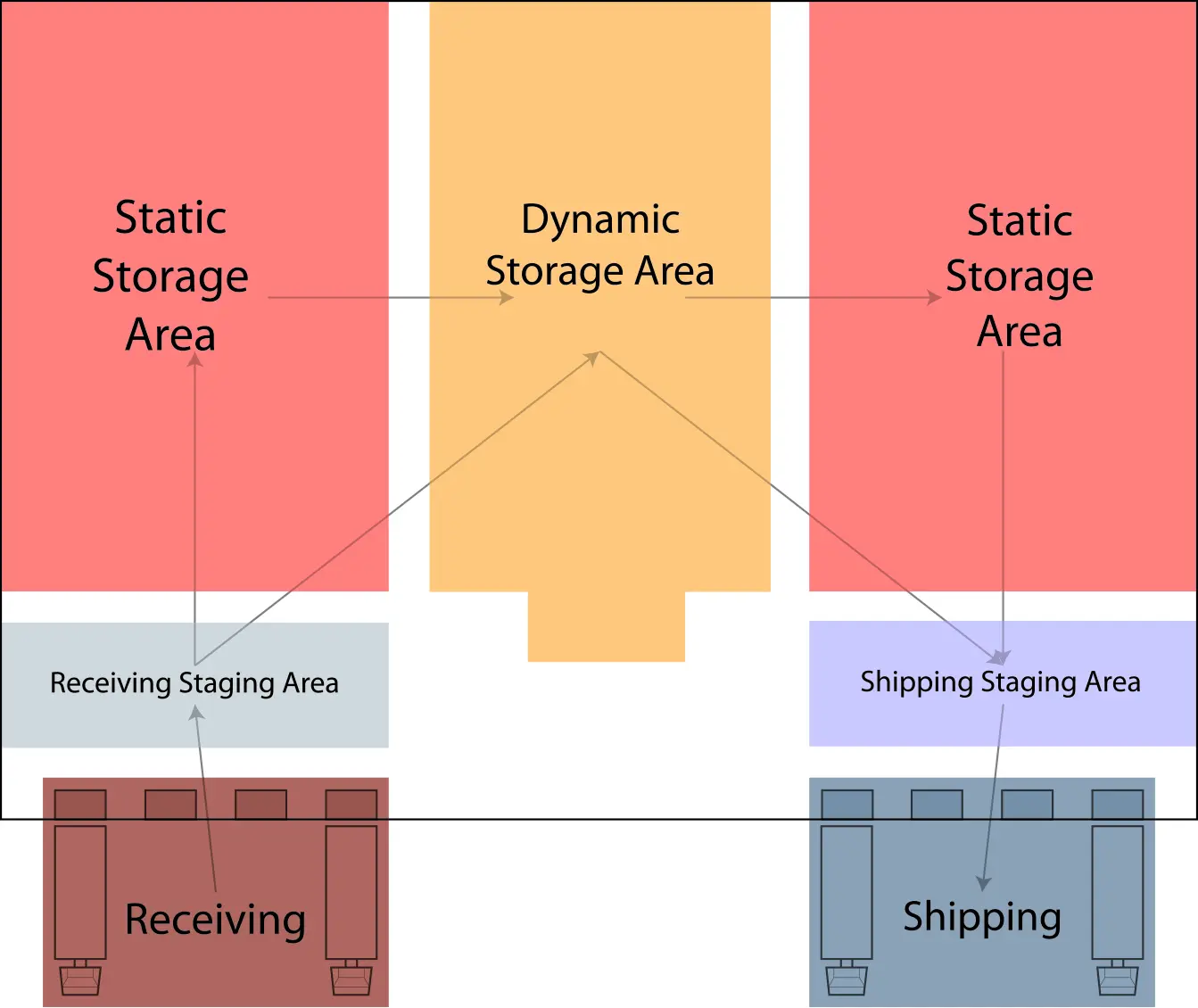

Your warehouse product flow determines your overall productivity and efficiency. When designing the overall layout of your warehouse the shipping and receiving placement should be evaluated and chosen based on your available space, product throughput needs, and available resources.

Pallet Racking Safety Guidelines: What They Are and How to Comply

Pallet racking safety guidelines should be followed for all steel industrial pallet rack systems. These guidelines are established by the American National Standards Institute (ANSI) as well as the Occupational Safety and Health Administration (OSHA). These are intended to ensure your employees and products remain safe.

Very Narrow Aisle Racking (VNA) vs. Standard Selective Racking

The most commonly used type of pallet rack system in distribution centers is selective rack. This is a versatile system that suites a wide variety of operational features.

There are options within selective rack to make this type of system best suite your space, SKUs, and picking processes. One of these options is a very narrow aisle racking system, commonly referred to as a VNA racking system. Read below to understand the differences versus standard selective rack and which may suite your operation.

Double Deep Pallet Racking vs. Standard Selective Racking

The most commonly used type of pallet rack system in distribution centers is selective rack. This is a versatile system that suites a wide variety of operational features.

There are options within selective rack solutions to make this type of system best suite your space, SKUs, and picking processes. One of these options is double-deep pallet racking. Read below to understand the difference compared to standard selective pallet racking and which may better suite your operation.