Retail Warehousing Services & Retail Storage Systems

Home / Industries Served / Retail

In retail, product placement and presentation go hand-in-hand with sales. Having an attractive space that is easy to navigate and well-organized helps ensure overall customer satisfaction and makes stocking and inventory more efficient.

At REB Storage System International, we understand how important product display and storage is to the success of your store. With 50 years of experience in the field, we have built a solid reputation on our ability to match the needs of retail spaces with the best storage systems.

Do you need a material handling solution for your retail backroom or distribution center?

To find out more about why you should partner with REB on your next storage project, call us at (800) 252-5955 or fill in the contact form on this page. We would love the opportunity to discuss what challenges you face and how we can help.

Submit Your Inquiry

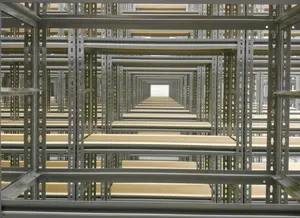

Individualized Designs

REB Storage Systems International knows that every retail space is unique. We create custom warehouse rack designs for all of our storage systems, ensuring that your products are ideally displayed in an attractive way that encourages customers to buy and visit your location again. Our systems are designed with material that meets the RMI standards with a clear understanding of OSHA’s requirements

Professional Installation

REB Storage Systems International has teams of professional warehouse rack installers who implement our designs and make them a reality in your space, never losing sight of a safe environment for both themselves and your employees. We use only the finest racking and shelving products and our installers take the time to ensure that your project is completed to the exact specifications of our designs.