Manufacturing

Home / Industries Served / Manufacturing

While manufacturing facilities can vary widely on the items they produce, they all need this production to run smoothly and efficiently. Often, there are a lot of moving parts and numerous areas that work together to fabricate and assemble items and get them shipped to distributors or end-users. Because of this, it's important that every area of the manufacturing facility is operating at peak performance.

As a material handling systems integrator since 1962, REB Storage Systems has the experience necessary to deliver a solution that will allow all the moving parts of your manufacturing facility to work together efficiently.

How do we approach this? First, we work with you to gain an understanding of your products. From there, we provide designs until the optimal solution is decided upon. Once the layout of the storage system is finalized, we make it all come together by arranging all deliveries, providing a professional installation, and conducting a final walk through with your team and, if required, the Village Inspector.

Do you need a material handling solution for your manufacturing facility?

To find out more about why you should partner with REB on your next storage project, call us at (800) 252-5955 or fill in the contact form on this page. We would love the opportunity to discuss what challenges you face and how we can help.

Submit Your Inquiry

Creating the Right Solution

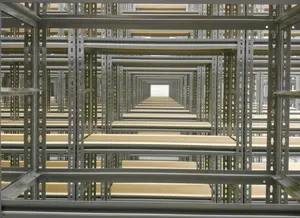

Incorporating the right types of racking will make it easy to store, navigate, and locate products while giving you more space in your manufacturing facility.

After assessing your space and products, REB project designers will design your rack system with one or more of the following racking types:

- Selective rack

- Pallet flow rack

- Carton flow rack

- Drive-in rack

- Drive-through rack

- Cantilever rack

- Push back rack

Additionally, REB project designers can design a pick module for your operation. A pick module integrates material handling products, such as conveyors, and other items, such a mezzanine, into the racking design of your storage solution to consolidate space and create optimize the flow of operations. When designed correctly, a pick module will reduce or eliminate walking time.

The Difference of a Customized Approach

REB Storage Systems International is different from other racking companies in that we have extensive project design and project management departments that ensures your rack system is optimized for your space and is completed on time and within budget.

Services include:

Design: Our services begin with a full assessment of your warehousing and distribution needs, which takes into account the layout of your space, the characteristics of your inventory and the material handling procedures that your team uses on a daily basis. We will then give you details on the type(s) of racking and layout that is ideal for you.

Project Management: REB manages all sub-contractors and continuously monitors the progress of the entire project so that it is completed on time and within budgetary guidelines.

Installation: REB’s professional installation team is highly experienced. We incorporate the best racking and decking products from a variety of top manufacturers, so we have the flexibility to use the best materials for your individual warehouse or distribution center. We can also incorporate used racking, if available, upon request.

Permitting support: A major advantage of using REB is that we can help secure the necessary permits for your project.