Warehouse Automation Systems

Automation is becoming more and more prevalent in warehouses, and for good reason. Warehouse automation systems provide huge advantages.

When considering if warehouse automation systems are right for you, some examples of things to consider are: how much does an error cost you? And going further, how much does a lost customer cost you? This can happen do to errors or ‘the other guy’ being able to get the product to the customer faster.

REB Storage Systems International offers automations systems tailored to your SKU profiles, available storage space, and product picking requirements.

In this article, you'll learn how each type of warehouse automation system works, advantages of implementing the right type of system, and how to identify which type(s) is right for you.

Advantages of Warehouse Automation Systems

Each of the warehouse automation systems will come with their own benefits. Advantages seen will also depend on how your warehouse is currently operating.

In general, here are some advantages commonly achieved when warehouse automation systems are introduced:

- Increased pick accuracy

- Product damage reduction

- Increased throughput

- Employee performance enhancement

- Increased storage density

- Employee training time reduction

Types of Warehouse Automation Systems Offered

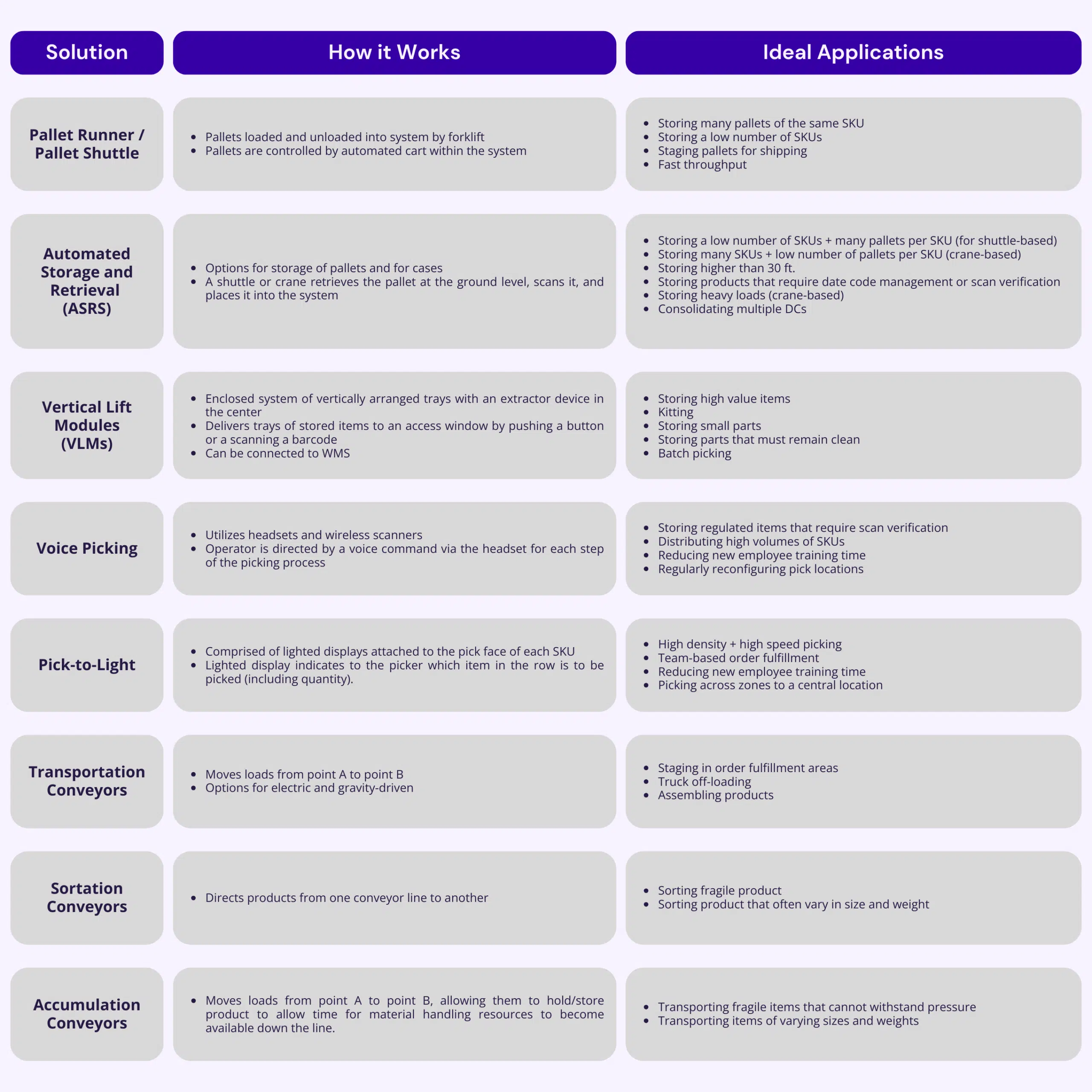

REB offers a wide range of warehouse automation systems, including conveyors, semi-automated pallet runners, fully automated pallet runners, automated storage and retrieval systems (AS/RS), pick-to-light, put-to-light, and voice picking. Read below for a brief overview on each type. For more details on each type, click on the product in our menu system or via the links in this section.

Conveyor Systems

There are a number of conveyor system options to suite a variety of operational requirements. Simply put, conveyors get products from point A to point B. There are many options to accommodate what needs to happen in-between point A and point B. Whether you need to divert products to different lanes, hold products in a queue, or get products from upper mezzanine levels to the ground level, conveyor systems will accomplish this for you.

Pallet Runners

Pallet runners are semi-automated deep lane storage systems that delivers pallets via a cart that runs on a track within the racking system. It's also commonly referred to as a pallet shuttle system. Pallet runners essentially allows the entire volume of your warehouse to be utilized. And the carts can be outfitted to suit a wide variety of pallet designs and can be used for first-in, first-out (FIFO) or last-in, first-out (LIFO).

Unit Load AS/RS Systems

A unit load AS/RS system, or automated storage and retrieval system, is an automated pallet storage solution that stores, tracks, picks and delivers pallets without human interaction other than dropping the pallet off and picking the pallet up. Unit load AS/RS generally falls into two categories: crane-based AS/RS systems and shuttle-based AS/RS systems.

Mini Load AS/RS Systems

A mini load AS/RS system, or automated storage and retrieval system, is an automated carton or tote storage solution that stores, tracks, picks and delivers cartons or totes without human interaction other than dropping off and picking up. A mini load system is a crane-based system.

Voice Picking Systems

Voice picking systems are automated picking systems that can be much more efficient than picking via paper or RF transmitters. With voice picking, the operator does not have to ‘look down’ to reference their next steps. This results in higher accuracy as well as seconds saved with each step the operator must make (which quickly adds up!).

Pick-to-Light & Put-to-Light

Pick-to-light systems and put-to light systems are comprised of lighted displays attached to the pick face of each SKU. The lighting configuration can be customized to the distribution center’s needs. These displays can be fixed to any type of racking or shelving system, whether it be existing or new build.

Vertical Lift Module

A vertical lift module, commonly referred to as a VLM, is an enclosed systems of vertically arranged trays stored in both the front and rear with an extractor device operating in the center.

Which Type of Automation is Right for You?

As described in the previous section, implementing automation in your warehouse will inevitably provide you with advantages. The key is identifying which type of automation is the best fit for your operation to ensure you see the maximum benefits.

The best way to figure out which type of automation system is the best fit for your operation is by consulting a material handling systems integrator, such as REB Storage Systems (here's how you can contact us). They will be able to assess your space, products, and growth projections, among other things, in order to present you with options.

However, to get you started, there are general operational features that make each type of automation solution a good fit.

Below is a general list of each. Also, view the below chart or video for a quick comparison of each type of automation solution.

Pallet Runners

- High number of pallets of the same SKU.

- Low number of SKUs.

- Requires staging pallets for shipments.

- Requires specialized pallet configuration.

- Fast throughput.

- Maintain good quality pallets.

Unit Load AS/RS & Mini Load AS/RS

- Low number of SKUs, high number of pallets per SKU (shuttle-based).

- High number of SKUs, low number of pallets per SKU (crane-based).

- Availability to store higher than 30 ft.

- Stores products that require date code management or scan verification.

- Stores heavy loads (crane-based).

- Freezer storage.

- Have multiple DCs that could benefit from being consolidated into one.

- Lack of availability of consistent warehouse labor.

Voice Picking

- DCs that distribute items which are regulated and require a scan verification.

- Large DCs that distribute high volumes of SKUs.

- DCs that fluctuate the number of workers needed based on seasons.

- DCs that regularly reconfigure pick locations.

Pick-to-Light and Put-to-Light

- Operations that have high-density, high-speed picking applications requiring 300-500 lines per man-hour pick rates.

- Distribution centers that have a team-based approach to order fulfillment, such as zone picking operations.

- Distribution centers that fluctuate the number of workers needed based on seasons. This is because less training is required for an employee to be able to pick properly.

Vertical Lift Module

- Operations that store high value items.

- Operations that use kitting as picking technique.

- Distribution centers that store small parts.

- Operations that store items that need to stay clean.

- Operations that perform batch picking.

- Multilingual operations.

Your Next Sep for Warehouse Automation Systems

REB is highly knowledgeable and experienced in designing and installing warehouse automation systems. As a systems integrator, we’ll work with you to provide a turnkey system. From design, products procurement, subcontractor management, install, and permitting support, REB handles it all for you.

REB has a talented team of in-house project managers and project designers, all highly experienced in the material handling industry. We’ll work with you to make sure that your system is the best fit for your operation, installed and completed on-time and within budget.

We’d appreciate the opportunity to help you further, whether that be more information or a quote. Fill in the contact form on this page or call us at (800) 252-5955 to get in touch with a REB representative.