Drive-In Racking & Drive-Through Racking Systems

Home / Products / Racking Products / Drive-in and Drive-through Rack

Drive-in racking and drive-through racking eliminates the need for down-aisle picking aisles. Both drive-in racking and drive-through racking offer a variety of benefits to warehouse efficiency.

REB Storage Systems International is a material handling systems integrator that provides full project management of drive-in and drive-through racking systems. Our services include design, permitting support, subcontractor management, procurement of materials, and installation.

Read below to learn more about REB’s drive-in racking and drive-through racking systems.

How Drive-In Racking & Drive-Through Racking Works

Pallets are stored on support rails that are attached to uprights and are accessed by a lift truck. The lift truck drives into the system with the load elevated to the height of the rail and places it in the selected storage location.

Drive-In Racking

- Lift truck loads and unloads by entering through the front and backing out

- Designed for last-in, first-out inventory

- Offers higher density but lower selectivity than drive-through rack

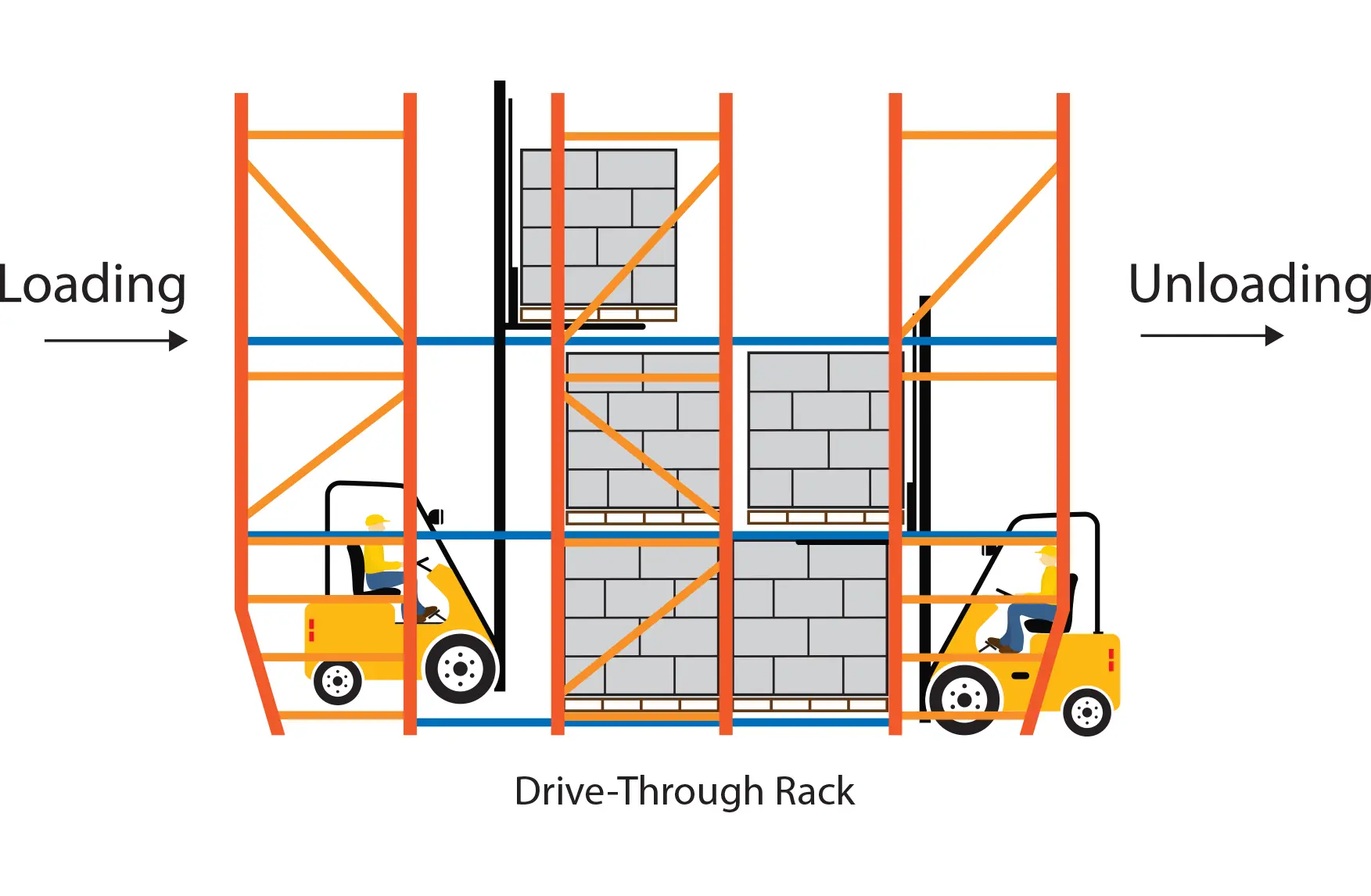

Drive-Through Racking

- Lift truck can enter through both ends of system for loading and unloading

- Designed for first-in, first-out inventor

Submit Your Inquiry

REB’s Turnkey Services for Drive-In Racking and Drive-Through Racking Systems

REB provides full project management of your drive-in racking and drive-through racking system. A REB project manager will be your point of contact throughout the project. Our project managers prioritize communication and will make sure that all applicable parties have a firm understanding of timelines and progression of the project.

Read below to better understand our drive-in racking and drive-through racking system project management services.

Design Services

The first step in REB's design services is to speak with your REB account executive so that we thoroughly understand the scope of your project. If necessary, we’ll conduct an onsite assessment. We want to make sure we understand your goals and current pain points so that we provide you with a solution that is optimized to your operation.

During the design process, we’ll obtain information such as your SKU profiles, space restrictions, and picking processes. We’ll work with you to ensure that your drive-in and drive-through racking system is set up to suit your requirements. For example, if you require your system to have a first-in, first-out or a last-in, first-out product flow.

Once all information is obtained, REB project designers will create a CADD drawing of your drive-in and drive-through racking system that suits all space and picking process requirements.

Permitting Support

If necessary, we’ll evaluate if permitting for your drive-in and drive-through racking system is required through our permitting support services. If permits are required, we’ll put together and submit all drawings and other documentation needed for permit approval. This often includes a high pile storage report.

Subcontractor Management

Once your drive-in and drive-through racking system design is finalized, your REB project manager will secure all suppliers and subcontractors. We’ll manage their involvement through the project. This includes freight and installation.

Our project management services prioritize communication and will make sure that all applicable parties have a firm understanding of timelines and progression of the project.

System Installation

REB Storage Systems has more than 60 years of professional experience installing material handling systems in warehouses nationwide. We’ll ensure that your operation’s drive-in and drive-through racking system is safely installed and compliant with MHI & OSHA standards while it optimizes your storage space and improves efficiency.

Key Features of Drive-In Racking & Drive-Through Racking

- Drive-in and drive-through racking systems have a number of options to aid in safe, efficient storage and distribution of products.

- Uprights located in areas of high traffic can be recessed, referred to as cant-back style, to lessen the likelihood of forklift impact.

- Floor-mounted guide rail and rack-mounted rub rail can also be included for further protection.

Is a Drive-In and Drive-Through Racking System Right For Your Operation?

In order to be certain that drive-in or drive-through racking will benefit your warehouse operations, you must understand the type of product flow this system requires to function properly.

The low selectivity of these racking systems make them ideal for storing large quantities. Products such as homogeneous products, products with long life spans, and products that require large, one-time moves.

Storage of products that require large, one-time moves.

Due to the high density these rack systems provide, they are very beneficial for cooler or freezer storage. Since coolers and freezers are expensive real estate, getting the most out of these areas for storage and efficiency is high priority. It is an excellent option for this.

Drive-through rack can also be used to store perishable items that are rotated quickly.

Advantages of Drive-In and Drive-Through Racking

There are many advantages to implementing drive-in racking and drive-through racking into your warehouse. Take the following advantages into consideration to decided if it may be the best option for you.

- Highly customizable

- Wide variety of heights and depths

- Includes option for both FIFO and LIFO

- High density, increases warehouse space

- Decreases storage expense of frozen/chilled goods

- Decreases stocking and picking time for bulk items of the same SKU

- Can be designed for specific pallet types

- Easily deconstructed and reconfigured if needed

Your Next Steps for a Drive-In or Drive-Through Racking System

Whether your next step is to gather more information or request a quote, consider REB Storage Systems. REB is a highly experienced systems integrator, in business since 1962. REB has 17 in-house project managers and project designers, all highly experienced in the material handling industry. These people know this industry inside and out.

REB is highly knowledgeable and experienced in designing, project managing, and installing drive-in racking systems and drive-through racking systems and will make sure your system is the best fit for your space. We work with you to provide a turnkey system. From design, products procurement, subcontractor management, install, and permitting support, REB handles it all for you.

We’d appreciate the opportunity to help you further, whether that be more information or a quote. Fill in the contact form on this page or call us at (800) 252-5955 to get in touch with a REB representative.

Case Studies To Consider

Double Density Drive In - Case Study

A family-owned tomato producer stacked products on their cooler floor for years. They turned to REB to provide them with a solution for better density and to improve overall operations.

Products: Drive-In Rack System

Services: Rack System Design, Permitting, and Instillation

Maximizing Mattress Density- Case Study

A mattress manufacturer needed to move from an existing 270,000 sq. ft. facility to a 130,000 sq. ft. facility.

Products: 2-Deep Drive-In Racking System

Services: Rack System Design, Permitting Support