Pallet Racking Types for Warehouse Storage & What to Consider

The industrial warehouse racking system serves as the entire framework for your operation. When choosing a warehouse racking system, you need racking solutions that are ideal for your space and built to last.

Your warehouse racking layout can include a small part of your space, or be used to furnish your entire warehouse. With a wide range of options to choose from, customizing your industrial warehouse racking to maximize density and efficiency will be a breeze. It can also be combined with various material handling storage solutions in order to suit your needs.

What To Consider When Choosing Types of Warehouse Racking Systems

At first, choosing the warehouse racking solution that will best benefit your operation may be difficult. There are many options to choose from and each racking type offers different benefits. To identify which is best for you, explore what factors you need to consider.

Before you start to assess what each racking solution offers, evaluate your warehouse space and operational goals. This includes deciding if shelving or racking is predominately needed in your space. For larger areas, items, or high product flow, industrial warehouse racks will probably be the most effective and efficient option.

Factors To Consider

When you are choosing a racking system for your warehouse, the rack you choose must agree with the type of products you are storing. Start by accessing what item(s) you will be storing.

Consider the product you will be storing and the way your operation is or will be run. Keep in mind many operations can and will utilize multiple racking systems. Now, answer the following questions about what your operation requires:

- What are my operation’s product flow requirements?

- Will my products be located on pallets or will I be piece picking?

- Do I require designated areas for picking and overflow storage?

- What is my available storage area including elevation?

- Will my operation require the utilization of a vehicle such as a forklift?

- Am I storing in a cooler or freezer?

What are my operation’s product flow requirements?

Product flow refers to how your product is moved throughout your operation. The two most common warehouse product flow types are first-in, first-out (FIFO) and last-in, first-out (LIFO).

FIFO storage compliments products that have an expiration date, such as food or beverage. FIFO storage can also be utilized when storing items that require rapid stock rotation or have a high turnover rate. The racking types that follow a FIFO product flow are drive-through rack, carton flow rack, and pallet flow rack. There is also an option to combine multiple racking types to create a pick module.

LIFO storage holds many benefits to an efficient warehouse operation. This system allows for product placed last into the racking system to be removed first. You should consider utilizing LIFO storage when you have product that has a long shelf life, or products that can be stored in bulk. If your operation requires LIFO storage, consider selective pallet rack, drive-in rack, push back rack, or combining racks to create a pick module.

Am I storing on pallets or piece picking?

When it comes to pallet storage, there are many options of rack available. This includes selective rack, push back rack, pallet flow rack, drive-in rack, and drive-through rack.

If you are looking to piece pick, carton flow rack provides options for consistent-sized cartons or cartons that vary in size. Carton flow rack also has options available such as tilt trays for the discharge end for an easier picking.

You can also incorporate bins with a selective rack system to accommodate piece picking.

The next section provides an in-depth analysis on the way each rack can be utilized.

Do I require designated areas for picking and overflow storage?

Incorporating dynamic and static storage areas can help improve throughput. Your warehouse layout and nature of your product flow will determine where your dynamic and static storage areas should be within the warehouse.

Dynamic storage, also known as forward pick, is the section of warehouse in which items are consistently picked for order fulfillment. In this area, high selectivity is vital to a successful operation, therefore often integrates multiple types of racking to reduce overall pick time, also known as a pick module.

The static storage area of a warehouse is where the overflow of products is stored, typically on pallets. This section of the warehouse is also referred to as the reserve storage area. Once products in the dynamic storage area are picked, pallets are retrieved from static storage for replenishment.

What is my available storage area including elevation?

Consider the size and shape of your warehouse. Do you have areas that are elevated? How tall is the space from floor to ceiling? How deep would you like your storage to be? How wide must the aisles be? Do you require a vehicle such as a forklift?

Knowing the answer to these questions will provide a greater understanding of how your warehouse layout should look. This will also allow you choose the correct racking type to best suit your desired warehouse product flow. For example, if your warehouse has high ceilings and you are looking to store non-perishable items in bulk, you may want to consider push back rack. This system can go as high as needed and typically stores products 2-6 pallets deep. The next section contains detailed information about the best uses for each rack.

Will I be utilizing a vehicle such as a forklift?

Systems allow for either manual or forklift picking. Push back rack only allows for picking and replenishment via a forklift. If you are looking for a system to conduct manual picks, carton flow rack is an option to consider. Another option for manual picks is implementing a pick module. A pick module can offer you both pallet storage and piece picking. If you choose to go this route, a conveyor may be added to offer manual picks.

There are many warehouse vehicle options available. Most racking types allow for the use of a standard forklift. Although, there are times that a standard forklift may not work and another vehicle may be required.

Keep in mind, if you are storing any type of bulk item or material located on a pallet, this will most likely require the utilization of a vehicle.

Am I storing in a cooler or freezer?

Consider both the environment of your warehouse, and the environment that your product requires. If you are storing product that requires cooler or freezer storage accessed by a lift truck, it is recommended to use structural steel rack. Structural steel rack has greater frame strength and durability, allowing it to better withstand impact in these environments.

If you are storing product that allows for hand picks of chilled or frozen goods, roll formed rack may be used. Due to low risk of damage hand picking offers, the decreased toughness of the cold storage racking system is not a factor. Roll formed racking is cost effective compared to structural. Additionally, because the beams are attached to the uprights by inserting corresponding-shaped connectors as opposed to bolts, roll formed rack can be more easily adjusted and reconfigured.

All pallet racking types can be manufactured from structural and roll formed steel, so no matter which type of steel you’ve identified as the best fit for your operation, there are several racking system options to choose from. The next section contains an in-depth analysis of each of the racking types.

Industrial Warehouse Racking Types

Now that you understand the factors that go into choosing an industrial warehouse racking system, keep your operational goals in mind when reading about each of the racking options. This section will provide you with a better understanding of how each racking system works, its ideal uses, and its key features. You can also view this video for a comparison of the different racking types.

Selective Pallet Rack

How It Works

- Pallets are loaded and unloaded from the front via lift truck

- Enables direct access to all pallets or cartons without needing to move others

Ideal Uses

- A warehouse or distribution center setting

- Continuous product circulation

- Require access to all palletized items simultaneously

- Storage of retail product, food, and beverage – although can store many other items

- May be used for reserve storage

Key Features

- Most common racking type

- Offers high selectivity with lower density

- Most common bay size 96″ wide x 42″ deep

- Last-In, First-Out (LIFO) inventory management

Drive-In And Drive-Through Rack

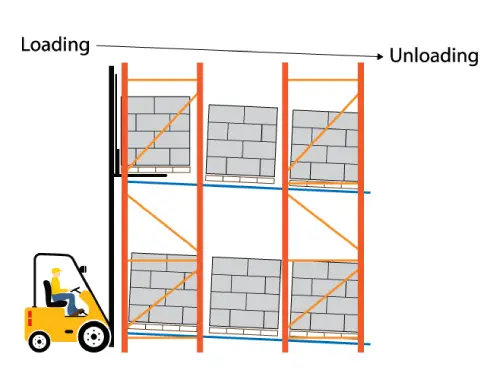

How It Works

- Drive-In Rack: Lift trucks load and unload by entering through the front of the system and then back out

- Drive-Through Rack: Lift trucks can enter through both ends of the system for loading and unloading. Drive-Through Rack can be convenient but will require an additional aisle.

Ideal Uses

- Storing large quantities of homogeneous product

- Storing products with long life spans

- Storing products that require large, one time moves

- Drive-through rack can be used to store perishable products or items with quick rotation

Key Features

- Offers both LIFO and FIFO storage:

- Drive-In: Last-In, First Out (LIFO)

- Drive-Through: First-In, First-Out (FIFO)

- Eliminates the need for down-aisle picking aisles

- Drive-In rack offers higher density than Drive-Through Rack

- Low selectivity, higher density

- Can support cooler or freezer storage

Cantilever Rack

How It Works

- Easily store and retrieve products varying in weight, length and size

Ideal Uses

- Ideal for storage of product that cannot be stored on a typical pallet

- Storage of lumber, furniture and plumbing

Key Features

- Easy arm adjustability

- Easy product accessibility

- Provide full range of loading capabilities

- High versatility- customize to your storage application

- Easy to deconstruct and reconfigure as needed

Push Back Rack

How It Works

- The rack supports carts that move along inclined rails.

- Push back systems utilize the warehouse cube to reduce required aisle space and maximize product storage

Ideal Uses

- Storage of frozen or chilled products

- Storage of products 2-6 pallets deep

Key Features

- Last-In, First-Out (LIFO)

- Variety of configurations available with bay widths that accommodate single-wide or double-wide pallet rows

- High density storage

- Rack can be as high as needed

- Allows access to multiple groups of SKUs simultaneously

- More efficient picks, each lane can hold a particular SKU

Carton Flow Rack

How It Works

- The rack supports inclined rollers or wheels that allow cartons to glide from the back (loading) aisle to the front (picking) aisle.

- Gravity system that provides excellent volume utilization.

Ideal Uses

- Storage of frozen or chilled product

- High volume case-pick and piece-pick

Key Features

- First-In, First-Out (FIFO)

- Highly customizable

- Offers high durability

- Decreases pick times

- Option to add breaks for speed control

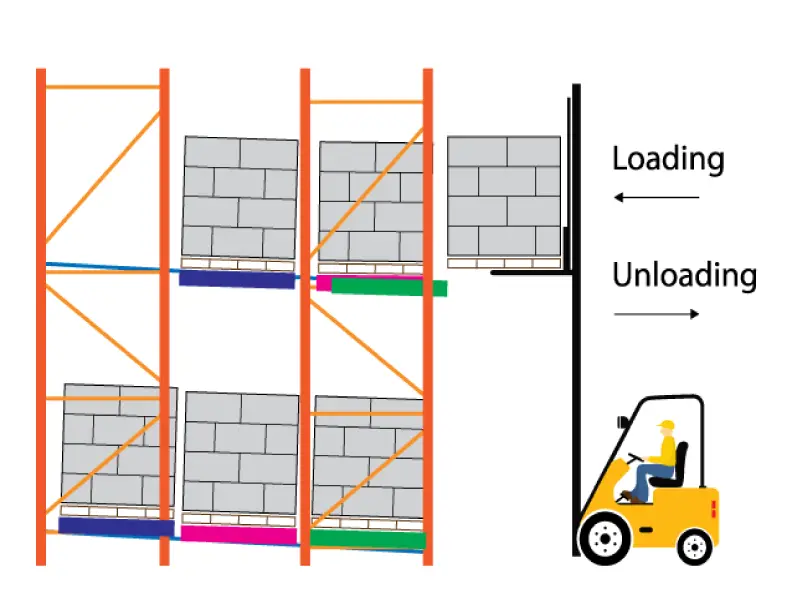

Pallet Flow Rack

How It Works

- Designed for larger inventory movement on pallets

- Supports inclined rollers or wheels that allow cartons to glide from the back (loading) aisle to the front (picking) aisle.

Ideal Uses

- Storage of frozen or chilled product

- Materials that vary in size

- Best suits high quality pallets

Key Features

- First-In, First-Out (FIFO)

- Storage can range from 2-12+ pallets deep

- Option to be customized to suit your needs

- Offers high selectivity and high density

- Can be combined with other rack types to create a pick module

- Breaks can be included for speed control

Combining Multiple Rack Types Into A Pick Module

How It Works

- Warehouse pick modules can include a number of elements in one design to produce the optimal layout and flow process for your operation

- Pick module layouts vary, but often contain areas to accommodate faster moving and slower moving products and/or palletized products and piece picking

Ideal Uses

- Manual pick applications

- Automated pick applications

- A combination of both manual and automated

Key Features

- Customizable to your operation

- Reduce or eliminate walking time

- Saves labor costs

- Shortened time for order fulfillment

- Increased pick accuracy, selectivity, and density

- Can be comprised of multiple components mentioned above

- Can be one level or multiple levels

Your Next Step For Choosing Your Industrial Warehouse Racking

Whether you are confident on which warehouse racking system you need or if you are looking for more guidance, we are ready to assist you. Submit a form or call 773-232-2863 to get in touch with a REB expert. REB has 17 in-house project managers and project designers, all highly experienced in the material handling industry. These professionals know this industry inside and out.

REB is a highly experienced systems integrator, in business since 1962. REB can provide you with top knowledge and will work with you to provide a turnkey system. From design, products procurement, subcontractor management, install, and permitting support, REB handles it all for you.

There are a number of rack providers out there. Whether your next step is to gather more information or request a quote, consider REB Storage Systems.

Share this post:

Share this post:

Submit Your Inquiry

Since 1962

REB has completed more than 100,000 projects in 15 countries (including all 50 states) for more than 20,000 customers across 50 industries, with 70% of customers as repeat buyers.

This is made possible by our team that has more than 300 years of industry experience designing and project managing material handling systems.

Learn more about REB's award winning service.