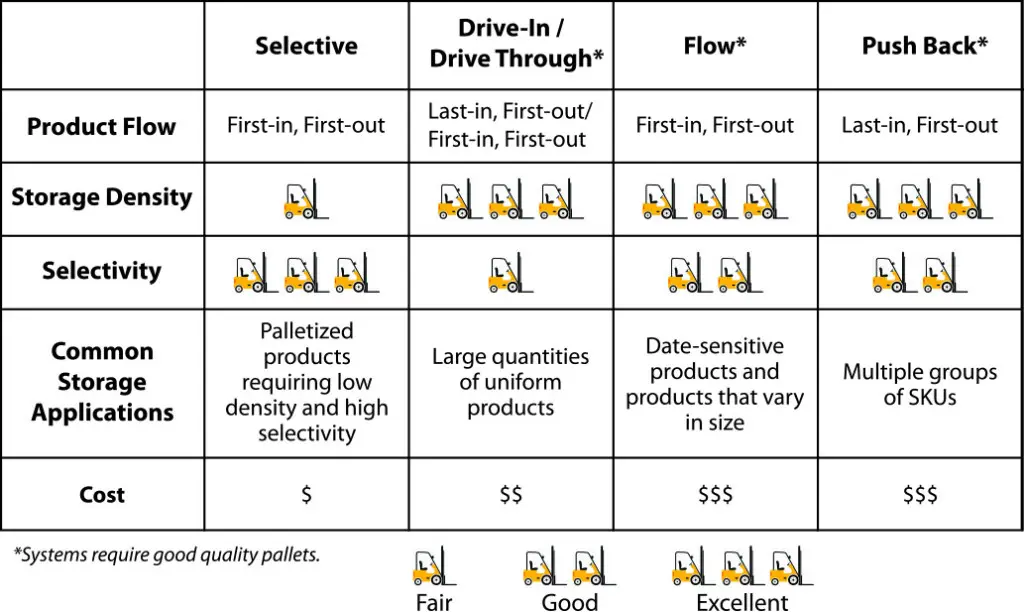

Pallet Racking Types: A Comparison Guide

There are various pallet racking types, all with different features, benefits, and ideal uses. Which is best for your operation not only depends on the products that you are storing but also the selectivity and density that you require. Below is a comparison and descriptions of pallet racking types.

Click here to read the video transcript

Pallet Racking Types Comparison Chart

Pallet Racking Types & Their Ideal Use Cases

Selective Racking & Ideal Uses

Selective rack is Designed for first-in, first-out (FIFO) inventory management. It enables direct access to all stored pallets or cartons without the need to move others, making it a highly selective solution where it is necessary to have a wide variety of products stored. Numerous aisles are required to accommodate this high selectivity, making it a lower density option compared to other types of rack systems. Double deep selective rack is also available for a LIFO inventory management option.

Selective rack is ideal for warehouses or distribution centers with continuous product circulation or that require access to all palletized items simultaneously.

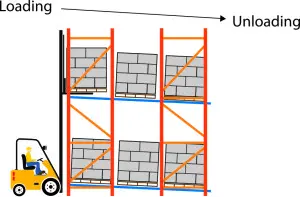

Drive-in and Drive-through Rack & Ideal Uses

Drive-in and drive-through racking is designed for last-in, first-out (LIFO – drive-in) or first-in, first-out (FIFO – drive-through) inventory management. Pallets are stored on support rails that are attached to uprights and are accessed by a lift truck that drives in to the system with the load elevated to the height of the rail and placed in the selected storage location. This provides high storage density by eliminating picking aisles, but offers low selectivity.

Drive-in and drive-through rack is ideal for storing large quantities of homogeneous products, products with long life spans, and products that require large, one time moves.

Pallet Flow Rack & Ideal Uses

Pallet flow rack is designed for first-in, first-out (FIFO) inventory management. Rack supports inclined rollers or wheels that allow cartons to glide from the back (loading) aisle to the front (picking) aisle. Brakes can be included for speed control. These gravity systems provide excellent volume utilization.

Pallet flow rack is ideal for materials with expiration dates, freezer or cold storage, food and beverage storage, and materials that vary in size.

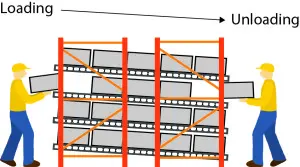

Carton Flow Rack & Ideal Uses

Carton flow rack is designed for first-in, first-out (FIFO) inventory management. Rack supports inclined rollers or wheels that allow cartons to glide from the back (loading) aisle to the front (picking) aisle. Brakes can be included for speed control. These gravity systems provide excellent volume utilization. Flow options are available to handle full cartons, split cases, or piece picking. Carton flow can be configured in many different ways, such as a stand-alone system, integrated with various pallet rack types, or within a multi-level pick module.

Carton flow rack is ideal for materials with expiration dates, freezer or cold storage, food and beverage storage, and materials that vary in size.

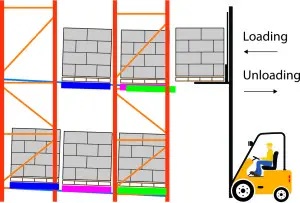

Push Back Rack & Ideal Uses

Push back rack is designed for last-in, first-out (LIFO) inventory management. Rack supports carts that move along inclined rails. Push back systems utilize the warehouse cube to reduce required aisle space and maximize product storage, making it a high-density pallet storage solution. A variety of layout configurations are available with variable bay widths to accommodate single-wide or double-wide pallet rows.

Push back rack is ideal for warehouses and distribution centers that require access to multiple groups of SKUs simultaneously, as well as freezer and cooler environments.

REB Storage Systems International offers all pallet racking types mentioned in this article. REB also offers project design and project management services on all projects, large or small, when you purchase the rack from us. To learn more visit our rack design page and our project management page.

VIDEO TRANSCRIPT

Hi and welcome to this edition of Total Warehouse Tutorials. In this video we will learn key differences between various types of pallet rack.

In this video we will be comparing selective rack, drive-in and drive-through rack, pallet flow rack, and push back rack on multiple key factors including product flow, storage density, selectivity, common storage applications, and cost.

Selective rack is designed for first-in, first-out product flow. It enables direct access to all stored pallets simultaneously, making it a highly selective solution. Numerous aisles are required to accommodate this high selectivity, making it a lower density option. Selective rack is ideal for operations with constant product circulation or that require access to all pallets at the same time.

In drive-in rack a lift truck loads and unloads through one end of the system, making it a last-in, first-out product flow option. In drive-through rack, the lift truck is able to load in one end and unload in the other, making it a first-in, first-out option. This method of driving into the system eliminates picking aisles, making it a high density solution but low selectivity. Drive-in and drive-through rack is ideal for storing large quantities of uniform products.

In pallet flow rack, the rack supports inclined rollers or wheels that allow pallets to glide from the back (loading) aisle to the front (picking) aisle, making it a first-in, first-out product flow option. Because this flow process provides continuous rotation of products, pallet flow rack is considered to offer moderate selectivity. Typical storage depth can range from 2-12 pallets deep, making it a high density storage option. Pallet flow rack is ideal for storing materials with expiration dates and materials that vary in size.

In Push back rack each pallet is loaded from the front of the system onto a cart. When the front pallet is unloaded, the next glides to the front for picking. This flow process makes push back rack a last-in, first-out option. Push back systems utilize the warehouse cube to reduce required aisle space, making it a high-density pallet storage solution with moderate selectivity. Push back rack is ideal for operations that require access to multiple groups of SKUs simultaneously.

General cost comparisons for these rack systems highly depends on the complexity of the system. For example, the cost to design, supply, and install selective rack is lower compared to drive-in and drive-through rack. Pallet flow and push back are highly complex designed systems with more components and therefore commonly come with a higher cost.

That’s it for this edition of Total Warehouse Tutorials. I hope you join us for our next edition on pick modules.

REB project designers take into account the layout of your space, the characteristics of your inventory, and the material handling equipment that your team uses. Clearly defining these requirements allows REB to develop the ideal solution as well as provide alternative solutions based on your budget and time frame. Each design meets both local and federal building codes. No matter what the needs of your space, we can create a professionally designed solution that will help you manage your inventory.

We also stock a large inventory of used industrial storage racks.

For more information on how to optimize your warehouse racking layout, fill in the contact form or call (800) 252-5955.

Share this post:

Submit Your Inquiry

Since 1962

REB has completed more than 100,000 projects in 15 countries (including all 50 states) for more than 20,000 customers across 50 industries, with 70% of customers as repeat buyers.

This is made possible by our team that has more than 300 years of industry experience designing and project managing material handling systems.

Learn more about REB's award winning service.