Transportation Transformation – A Case Study

Solution at a Glance

- Services Provided: Rack Safety Inspection

- Products Provided: Rack Repair Kits

- Location: Forest Park, IL

Concern: Unsafe Rack Conditions

A Chicagoland 3PL company had concerns about unsafe rack conditions in their facility.

The company never had a rack safety inspection done. This caused them to be concerned about the safety of their employees and assets.

Additionally, their rack system has very narrow aisles (VNA), making damage more likely to accumulate. This is also more challenging to repair and/or replace compared to a rack system with standard aisles.

Solution: Rack Safety Inspection

REB conducted an on-site safety inspection of the company’s rack system.

The safety assessment found a total of seventy-four areas where the pallet rack frames were damaged and required repair. Two uprights were damaged beyond repair and in jeopardy of collapse. Thankfully, the inspection

allowed them to address these major concerns before the situation worsened.

After the inspection, REB presented the company with a scope drawing. This detailed the location of each type of damage. As a result, the company was able to clearly assess all safety concerns and identify which repairs they’d like to have completed.

To better understand our rack safety inspection process, click here to be directed to our rack safety inspection service page.

Solution: Rack Repair

REB repaired the company’s rack in accordance with ANSI/RMI standards.

After reviewing the results, the company went ahead with the nine most urgent rack repairs. This included seven single column rack repairs and two replacement frames. The two frames that were replaced were damaged beyond repair and could not support any reasonable load capacity without posing a danger of collapsing.

REB’s professional rack repair is in accordance with industry requirements. The guidelines for rack safety and repair are established by the American National Standards Institute (ANSI) and Rack Manufacturer’s Institute (RMI). These standards can be found in ANSI/RMI 16.1. Of these, two pertaining to rack repair are as follows:

- Repair and Replacement of Damaged Components: These shall be replaced by qualified persons following recommended and documented procedures. Repair components must be at least as strong as undamaged components. The repair process (assessment, design, and installation) should be overseen by a qualified rack design engineer (supervising engineer). The assessment and design of rack repairs should address all loads that can be imparted on damaged members (static, seismic, etc.), not just on the specific members being repaired.

- Additions, Alterations, and Reconfigurations: All additions, alterations and reconfigurations should be reviewed by a qualified engineer to ensure any changes meet the same requirements as the original installation. Engage a licensed professional engineer to review the proposed racking configurations.

REB’s rack repair kits and installation ensure that companies comply with these standards.

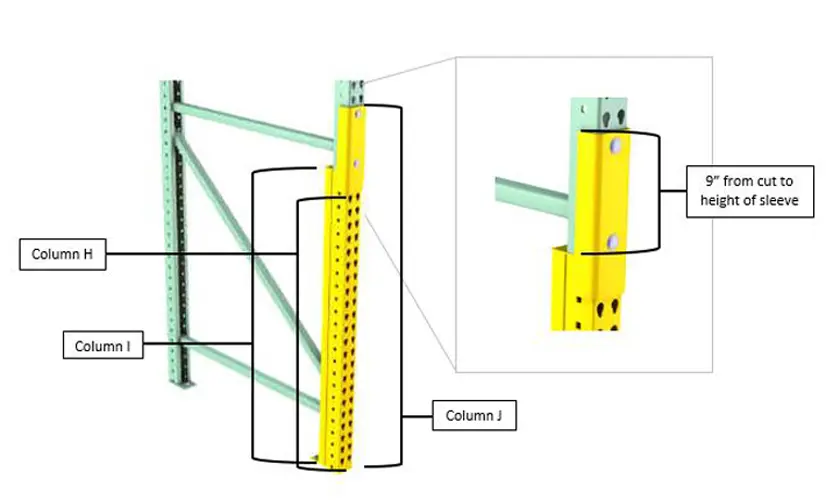

The repairs for the 3PL company were completed by following a multi-step process. These steps included:

- Pallets on floor and first beam level were removed. All other levels were able to remain loaded.

- REB attached the rack-lifting jack, removed the anchors, and removed the damaged portion of the upright.

- The channel was inserted, clamped, and bolted into place.

- The rack-lifting jack was removed, and the inventory was replaced.

Since the aisles were very narrow, special rack repair kits suited for that space were used.

To better understand our rack repair process, click here to be directed to our rack repair service page.

Outcome: A Safe and Compliant Rack System

The once damaged rack that was repaired by REB now complies with all ANSI/RMI rack safety regulations. With the repairs that were made, daily operations and employees are in a much safer working environment.

The company now knows the locations of all remaining rack damage and can budget to have these repaired. REB is slated to return to the location to conduct further repairs.

How You Can Achieve a Safe, Compliant Rack System

If you have concerns that your rack system is unsafe, contact REB today.

We have a dedicated team of rack safety professionals who conduct rack safety inspections for our nationwide customer base. We are highly experienced in identifying rack safety concerns and staying up to date on all rack safety regulations.

We’d appreciate the opportunity to help you further, whether that be more information or a quote. Fill in the contact form on this page or call us at (800) 252-5955 to get in touch with a REB representative.

Share this post:

Submit Your Inquiry

Since 1962

REB has completed more than 100,000 projects in 15 countries (including all 50 states) for more than 20,000 customers across 50 industries, with 70% of customers as repeat buyers.

This is made possible by our team that has more than 300 years of industry experience designing and project managing material handling systems.

Learn more about REB's award winning service.