Selective Pallet Rack

Home / Products / Racking Products / Selective Rack

Selective rack is the most common type of racking system. It enables direct access to all stored pallets or cartons without the need to move others. This makes it a highly selective solution. REB project designers can assess your operation to provide you with your best layout.

REB Storage Systems International is a material handling systems integrator that provides full project management of selective pallet rack systems. Our services include design, permitting support, subcontractor management, procurement of materials, and installation.

Read below to learn more about REB’s selective pallet rack systems.

How Selective Pallet Rack Works

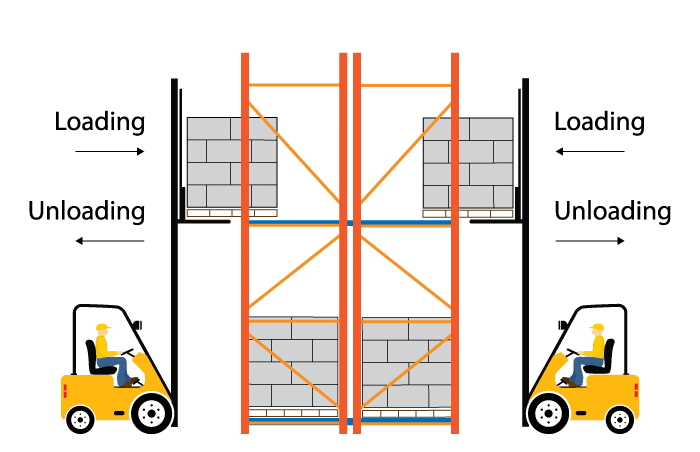

In selective rack, pallets are loaded and unloaded from the front via a lift truck. Selective rack is available in both single-deep and double-deep.

Single-Deep Pallet Rack

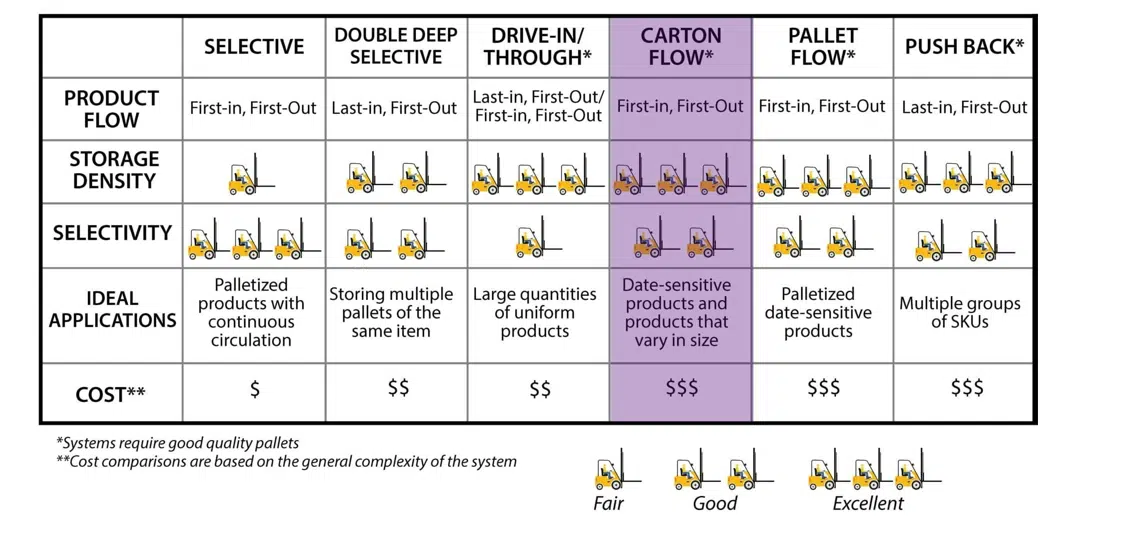

- Designed for first-in, first-out inventory management.

- Numerous aisles required.

- Aisles can be configured as standard size or very narrow aisle (VNA).

Click to see a comparison of selective rack with very narrow aisles versus standard aisles.

Double-Deep Pallet Rack

- Consists of two standard selective racks set up back to back.

- Designed for last-in, first-out inventory.

Click to see a comparison of double-deep selective rack versus single-deep.

Submit Your Inquiry

REB’s Turnkey Services for Selective Pallet Rack Systems

REB provides full project management of your selective pallet rack system. A REB project manager will be your point of contact throughout the project. Our project managers prioritize communication and will make sure that all applicable parties have a firm understanding of timelines and progression of the project.

Read below to better understand our selective pallet rack system project management services.

Design Services

The first step in REB's design services is to speak with your REB account executive so that we thoroughly understand the scope of your project. If necessary, we’ll conduct an onsite assessment. We want to make sure we understand your goals and current pain points so that we provide you with a solution that is optimized to your operation.

During the design process, we’ll obtain information such as your SKU profiles, space restrictions, and picking processes. We’ll work with you to ensure that your selective pallet rack system is set up to suit your requirements. For example, if you require your system to have a first-in, first-out or a last-in, first-out product flow.

Once all information is obtained, REB project designers will create a CADD drawing of your selective pallet rack system that suits all space and picking process requirements.

Permitting Support

If necessary, we’ll evaluate if permitting for your selective pallet rack system is required through our permitting support services. If permits are required, we’ll put together and submit all drawings and other documentation needed for permit approval. This often includes a high pile storage report.

Subcontractor Management

Once your selective pallet rack system design is finalized, your REB project manager will secure all suppliers and subcontractors. We’ll manage their involvement through the project. This includes freight and installation.

Our project management services prioritize communication and will make sure that all applicable parties have a firm understanding of timelines and progression of the project.

System Installation

REB Storage Systems has more than 60 years of professional experience installing material handling systems in warehouses nationwide. We’ll ensure that your operation’s selective pallet rack system is safely installed and compliant with MHI & OSHA standards while it optimizes your storage space and improves efficiency.

Key Features of Selective Pallet Rack

- Highly selective

- This requires numerous aisles, which makes it a lower density option

- Double-deep pallet racking allows for greater density than single-deep pallet racking

- Can be integrated with other systems to create a pick module

- Common bay size for selective rack is 96" wide x 42" deep

- However, there are many different bay configurations possible

- Bolted cross bars are available to support pallets

- Wire decking can be used to support pallets, totes, or boxes

Is a Selective Pallet Rack System Right For Your Operation?

Selective Pallet Rack can be used for a number of applications from retail, food and beverage, along with many others. Consider these qualities to understand if selective pallet rack will benefit your operation.

High accessibility to products makes it ideal for distribution centers with continuous product circulation or that require access to all pallets simultaneously.

The continuous product circulation flow selective pallet racks offer allows for a high turnover rate.

Selective pallet rack systems can also be used for reserve storage of products, to replenish picking areas when needed.

Advantages of Selective Pallet Rack

With selective pallet rack being the most common racking type, there are many advantages to using selective pallet rack for your operation.

- Increased storage capacity

- Increased inventory management ease

- Decreased product transport time

- Compatible with most standard forklifts

- Design allows for easy reconfiguration to suit specific products

- Relatively low cost

Your Next Step for a Selective Pallet Rack System

Whether your next step is to gather more information or request a quote, consider REB Storage Systems. REB is a highly experienced systems integrator, in business since 1962. REB has 17 in-house project managers and project designers, all highly experienced in the material handling industry. These people know this industry inside and out.

REB is highly knowledgeable and experienced in designing and installing selective pallet rack systems and will make sure your system is the best fit for your space. We work with you to provide a turnkey system. From design, products procurement, subcontractor management, install, and permitting support, REB handles it all for you.

We’d appreciate the opportunity to help you further, whether that be more information or a quote. Fill in the contact form on this page or call us at (800) 252-5955 to get in touch with a REB representative.

Case Studies To Consider

Selective Rack System Relocation

A company that sells office furniture was moving operations and required its current system to be removed and reinstalled in the new facility.

Products: Selective Rack

Services: Design, Installation, Teardown

Piece-Picking Pick Module- Case Study

A rapidly growing eCommerce company needed to expand their operations into a bigger facility to accommodate for their current and future growth.

Products: Selective Rack, Wire Decking

Industry: eCommerce

Various SKU Storage- Case Study

A hardware supplier was opening two new distribution centers: a 410,000 sq. ft. facility in Ohio and 290,000 sq. ft. facility in California.

Products: Selective Rack, Cantilever Rack

Services: Design, Installation

Submit Your Inquiry

Testimonials

More Racking Product Options: