Selective + Mobile Rivet Shelving + Pick Carts + Dock Bumpers for Countrywide Retail Backrooms – A Case Study

Solution at a Glance

Learn how REB’s tailored retail backroom designs increase storage density, improve pick rates, reduce vendor complexity, and support on-time openings for a major national retailer.

- Services Provided: Design, Project Management, Installation, Permitting Support

- Products Provided: Selective Pallet Rack, Rivet Shelving, Mobile Rivet Shelving, Pick Carts, Dock Bumpers, Dock Seals

- Location: Numerous Locations Countrywide

- Number of Projects REB has Completed for Customer: 22

Concern: Insufficient Resource for Countrywide Backroom Storage Needs

A large sporting goods retailer was experiencing problems maintaining a reliable source for their countrywide backroom storage needs. The retailer’s backrooms varied from store to store. Staff often stored items wherever space was available, slowing pick times and wasting valuable storage space.

The retailer’s SKU range presents an additional storage challenge. Their products vary significantly in shape, size, and weight. Examples of products include varying sized balls, bats, fishing gear, golf clubs, shoes, and apparel. Because of this, they require a backroom storage solution that is tailored and versatile.

Instead of working with several companies to meet the needs of each location, they looked for a single partner capable of managing everything. This partner needs to scale with their growing demands as the business expands.

Solution: Countrywide Project Management and Design Source

The retailer partnered with REB Storage Systems International to design and install storage solutions tailored to their inventory for their stores across the United States. Working with REB is beneficial for the retailer because REB can handle every aspect of all backroom projects. This gives the customer the convenience of utilizing one company for all design work, materials, freight management, permitting, and installation.

Because each backroom has a different layout, REB designers do extensive work to design the racking and shelving plans to meet the needs of each location. The goal of every layout is to provide as much storage as possible in the limited backroom space while allowing employees to easily find and pick products.

As a systems integrator, REB leverages a broad network of manufacturers and installers to source products, including racking, shelving, decking, picking carts, dock bumpers, and dock seals.

Read further to learn more about each backroom storage solution REB provides the retailer.

Solution: Storage and Handling Solutions Tailored to Diverse Inventory

To effectively store the large range of products several storage solutions must be used. The storage and material handling solutions must provide easy access to all stored products while prioritizing density within the confined space of the backroom.

Selective Pallet Rack

Selective pallet rack with wire decking is used to store various sized boxes for hand picking as well as bulk storage. Additionally, selective rack is used to store products that require a unique storage setup. Selective rack is ideal for these types of tailored setups due to its ability to be easily customized.

Customized selective rack configurations used by the retailer include:

- Beams fitted with custom welded hooks to store baseball bats.

- Selective rack bays fitted with wire decking and wire mesh dividers to store items that may roll off the rack, such as various sports balls.

- Selective rack fitted with peg boards on the uprights facing the main aisles for versatile and adjustable storage of hanging products.

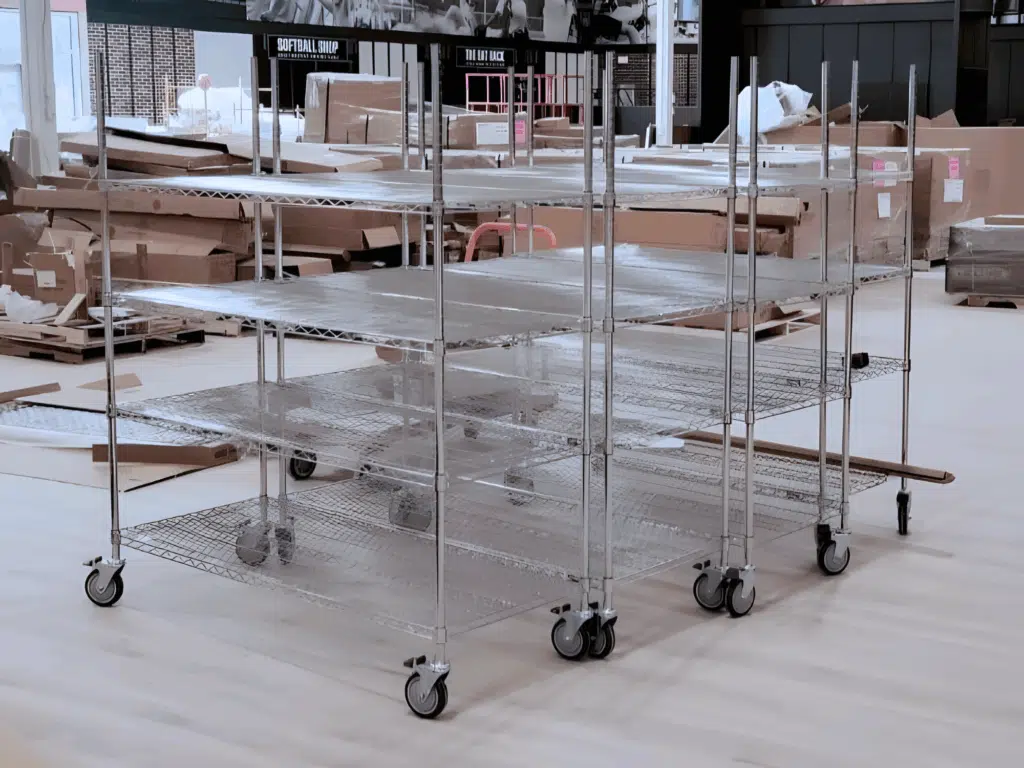

Mobile Rivet Shelving

Because space in the backroom of retail stores is limited, rivet shelving fitted to mobile bases are ideal. Mobile rivet shelving eliminates the need for permanent aisles between every row of shelving. Instead, all shelving units are compacted together. When an item is needed, the picker uses a handle to pull open a single aisle.

As a result, storage capacity can be increased by up to 80% compared to static shelving while maintaining access to all products. This makes mobile rivet shelving ideal for the limited space available in retail backrooms.

Static Rivet Shelving

Because static rivet shelving units are more cost-effective than mobile rivet, REB designers incorporate static rivet shelving to store SKUs that have low volumes, as well as in tighter areas of the layout that can only fit one or two shelving units.

Pick Carts

For easy and efficient transport of picked items REB supplies the retailer with wire pick carts. Wire carts are ideal because they provide durability and high visibility of products on the cart.

The wire picking carts have four shelf levels. This allows pickers to pick multiple products at once, reducing travel time. Open wire carts are used to transport bulky items and boxes, while enclosed wire carts are used to transport items that are at risk of falling off during transportation.

Dock Bumpers and Dock Seals

The retailer had concerns about their loading dock bumpers and seals not being effective in several locations. Ensuring these are working properly is important. Wrong-sized and poor-quality dock bumpers do not provide the protection needed to defend the building walls and foundation from being damaged by truck trailers.

Likewise, faulty dock seals will allow outside air to flow into the dock area and the inside heat or air conditioning to escape outside. Additionally, it can leave room for rain, dust, and pests to enter the facility, all causing unnecessary expenses.

REB asses the dock bumpers and dock seals at each project location. If deemed necessary, REB sources the highest quality bumpers and seals, removes the ineffective ones, and installs the new ones.

Outcome: Comprehensive Backroom Storage Strategy Nationwide

Since July 2024, REB has delivered 22 turnkey backroom storage solutions for the retailer across 14 states, with additional locations underway. REB continues to work with the retailer as new locations arise.

The retailer has seen several advantages as a result of working with REB. These include:

Time savings: The REB project manager is the retailer’s sole point of contact when implementing new or upgrading existing backroom storage layouts. This eliminates the need for the retailer to manage multiple vendors for every store, saving them valuable time.

Cost savings: Due to REB’s longevity as a systems integrator in the material handling industry, REB has an expansive network of manufacturers and installation subcontractors. This allows REB the flexibility to choose products based on the requirements of each retail backroom location, including pricing and lead time.

Ontime store openings: Retail timelines move quickly. REB manages schedules, coordinates with all vendors, and provides ongoing updates to ensure each backroom is completed before store opening dates.

Higher backroom storage density: The retailer’s backroom storage density has increased due to the customized storage configuration designed for each set of products. Tailoring the storage systems to their products allows the full cube of each backroom to be utilized. The mobile rivet shelving provides considerable storage density due to only needing one picking aisle at a time.

Increased pick rates: Products now have defined locations within every backroom, reducing search time and enabling faster picking. Four-shelf pick carts further increase productivity by allowing employees to pick multiple items in a single trip.

How To Transform Your Backroom Storage for Efficiency

Looking to improve your backroom storage? REB can help.

Our team of material handling specialists will partner with you to develop a customized solution that optimizes your backroom space. We bring proven expertise in designing and project managing storage systems that address the unique challenges of retail backrooms.

We’d appreciate the opportunity to help you further, whether that be more information or a quote. Fill in the contact form on this page or call us at (800) 252-5955 to get in touch with a REB representative.

Share this post:

Submit Your Inquiry

Since 1962

REB has completed more than 100,000 projects in 15 countries (including all 50 states) for more than 20,000 customers across 50 industries, with 70% of customers as repeat buyers.

This is made possible by our team that has more than 300 years of industry experience designing and project managing material handling systems.

Learn more about REB's award winning service.