Cold Storage Racking 101: Pick the Right Cold Storage Racks

Coolers and freezers present unique storage challenges. With cold temperatures and confined spaces, it’s crucial to incorporate a cold storage racking system that can withstand harsh conditions and maximize floor space.

If you’re implementing a storage system in your cooler or freezer, here’s information that can help you achieve system longevity and optimal space utilization.

Structural Steel vs. Roll Formed Steel For Cold Storage Racking

The Rack Manufacturer’s Institute stipulates that racking reaches what’s known as “ductile-brittle transition” at 0° Fahrenheit. This means that racking in an environment at or below this temperature is more sensitive to impact, increasing the likelihood of rack failure.

While many coolers and freezers do not reach this extreme temperature, this points to the fact that as the temperature in a storage environment decreases, so does the toughness of the racking system. Thus, while strength and load carrying capacity are not affected, if a forklift or other vehicle were to hit the rack structure, the likelihood of damage and even collapse are more likely.

When To Use Structural Steel Racking

Due to the effects of ductile-brittle transition, structural steel racking is recommended in coolers and freezers that use vehicles to access products.

Structural steel rack has greater frame strength, allowing it to better withstand impact in these environments. Structural steel rack is hot rolled, it’s components are then welded together. In addition, the beams are bolted to the uprights. These factors contribute to the overall strength of structural racking.

Structural steel rack has greater frame strength, allowing it to better withstand impact in these environments. Structural steel rack is hot rolled, it’s components are then welded together. In addition, the beams are bolted to the uprights. These factors contribute to the overall strength of structural racking.

When To Use Roll Formed Steel Racking

For operations that do hand-picking in a cooler or freezer, roll formed rack can be used. Because there is no risk of impact by a vehicle, the decreased toughness of the roll formed steel is not a factor.

Roll formed racking is cost effective compared to structural. Additionally, because the beams are attached to the uprights by inserting corresponding-shaped connectors as opposed to bolts, roll formed rack can be more easily adjusted and reconfigured.

Roll formed racking is cost effective compared to structural. Additionally, because the beams are attached to the uprights by inserting corresponding-shaped connectors as opposed to bolts, roll formed rack can be more easily adjusted and reconfigured.

Cold Storage Racking Options

All pallet racking types can be manufactured from structural and roll formed steel, so no matter which type of steel you’ve identified as the best fit for your operation, there are several racking system options to choose from.

Choosing the one that fits your product flow and characteristics of your inventory will ensure that your operation is at maximum efficiency. Read below and view the video in this section to learn about each type of cold storage racking system including how it works, ideal uses, and commonly seen advantages.

Selective Pallet Rack

How It Works

- Pallets are loaded and unloaded from the front via lift truck.

- Enables direct access to all pallets or cartons without needing to move others.

Ideal Uses

- A warehouse or distribution center setting.

- Continuous product circulation.

- Require access to all palletized items simultaneously.

- Storage of retail product, food, and beverage – although can be used to store other products.

- May be used for reserve storage.

Key Features

- Most common racking type.

- Offers high selectivity with lower density.

- Most common bay size 96″ wide x 42″ deep.

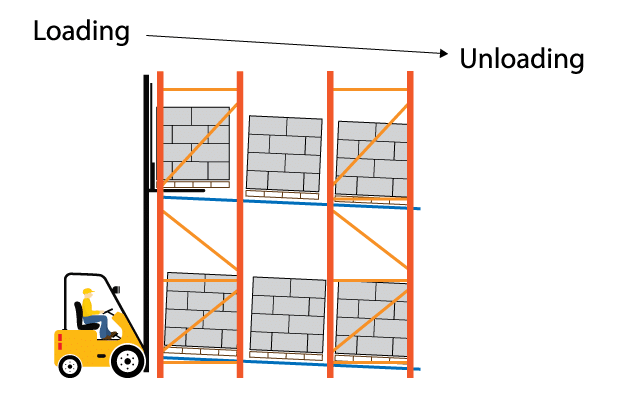

Pallet Flow Rack

How It Works

- Designed for larger inventory movement on pallets.

- Supports inclined rollers or wheels that allow cartons to glide from the back (loading) aisle to the front (picking) aisle.

Ideal Uses

- Storage of frozen or chilled product.

- Materials that vary in size.

- Best suits high quality pallets.

Key Features

- Storage can range from 2-12+ pallets deep.

- Provides excellent volume utilization.

- Customizable

- Offers high selectivity and high density.

- Can be combined with other rack types to create a pick module.

- Breaks can be included.

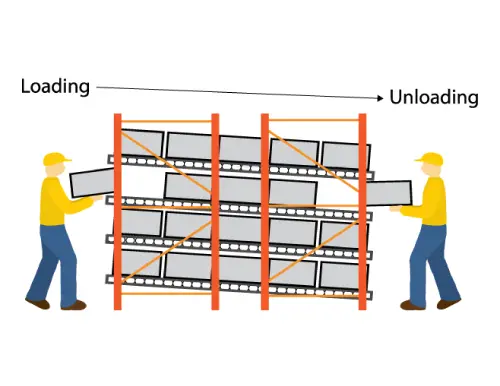

Carton Flow Rack

How It Works

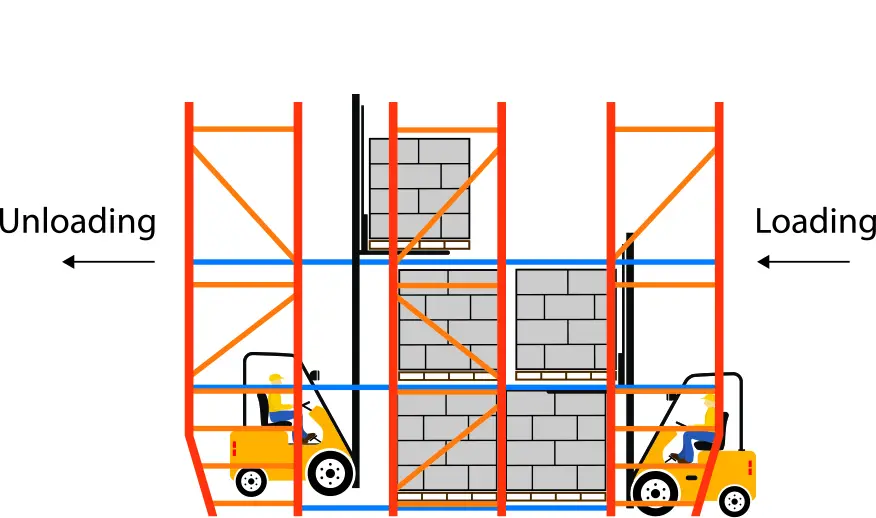

- Lift trucks are able to enter through both ends of the system for loading and unloading.

- Drive-through rack can be convenient, but require an additional aisle.

Ideal Uses

- A warehouse or distribution setting.

- Continuous product circulation.

- You require access to all palletized items simultaneously.

- Storage of retail product, food, and beverage – although can store many other items.

Key Features

- Eliminates the need for down-aisle picking aisles.

- Easily can be deconstructed and reconfigured as needed.

- High density allowing for increased warehouse space.

- Can be designed to suit specific pallet types.

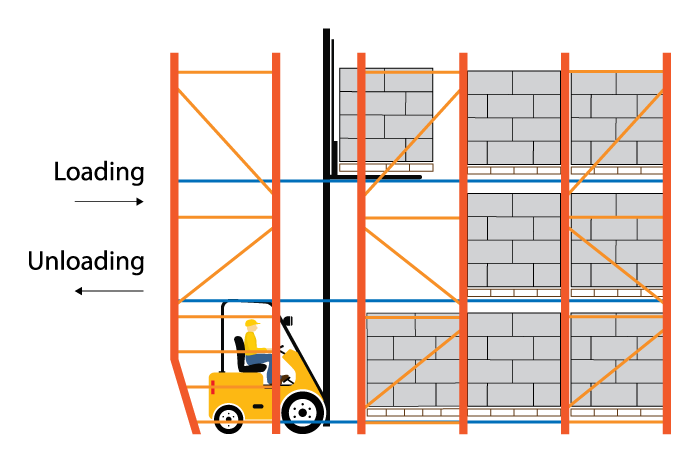

Drive-In Rack

How It Works

- Lift trucks load and unload by entering through the front of the system and then back out.

Ideal Uses

- Sorting large quantities of homogeneous product.

- Storing products with long life spans.

- Storing products that require large, one time moves.

Key Features

- Eliminates the need for down-aisle picking aisles.

- Drive-in rack offers higher density than drive through rack.

- Lower selectivity, higher density.

- Can support cooler or freezer storage.

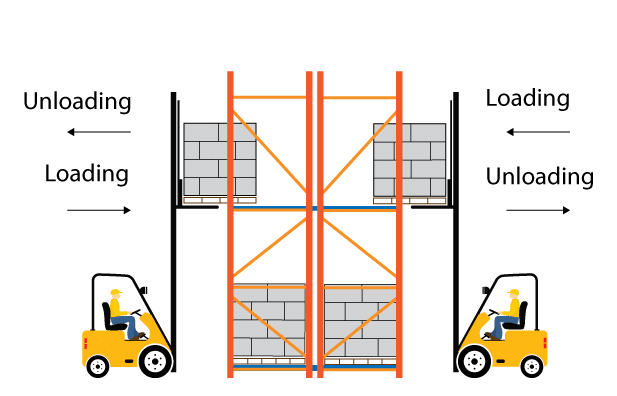

Drive-Through Rack

How It Works

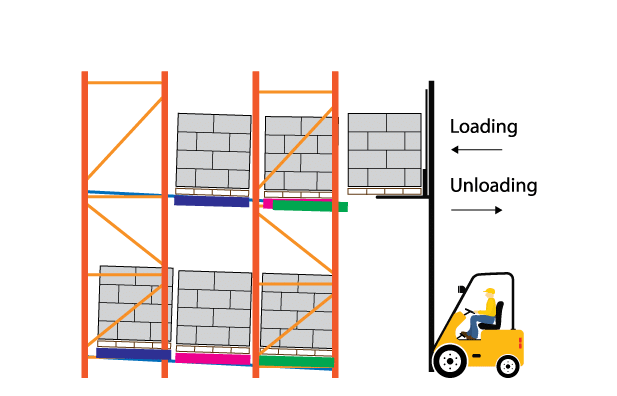

- The rack supports inclined rollers or wheels that allow cartons to glide from the back (loading) aisle to the front (picking) aisle.

- Incorporates gravity system that provides excellent volume utilization.

Ideal Uses

- Storage of frozen or chilled product.

- High volume case-pick and piece-pick.

- Can be combined with other rack types to create a pick module.

Key Features

- Highly customizable.

- Provides high density storage.

- Highly durable.

- Decreases pick times.

- Option to add breaks for speed control.

Push Back Rack

How It Works

- The rack supports carts that move along inclined rails.

- Utilizes the warehouse cube to reduce required aisle space and maximize product storage.

Ideal Uses

- Storage of frozen or chilled products.

- Storage of products 2-6 pallets deep.

Key Features

- Variety of configurations available with bay widths that accommodate single-wide or double-wide pallet rows.

- High density storage.

- Rack can be as high as needed.

- Allows access to multiple groups of SKUs simultaneously.

- More efficient picks, each lane can hold a particular SKU.

Why a Rack Supported Cooler and Freezer can be Ideal

If you’re currently researching options for an industrial cooler or industrial freezer for your warehouse, consider combining both of these steps by implementing a rack supported cooler or freezer.

Integrating a rack supported structure for an industrial cooler or freezer offers higher storage density because the system will serve as the structural base. This eliminates columns or any other structural obstructions, allowing optimal space utilization.

In addition to higher density, combining the storage system and framework reduces costs and building time. Since both structures are constructed simultaneously, the timeline is often shorter, allowing operations to resume quicker. Rack supported structures can be worked into an existing warehouse design without building modifications.

To read our case study on a rack supported cooler and freezer project, click here.

Your Next Step for a Cold Storage Racking System

Now that you have a better idea of which racking systems are ideal for a cold storage facility, we’d appreciate the opportunity to help you with the next step. Whether you are certain which system will work best for you or you are in need of more guidance, our experts are ready to assist you.

REB has a talented team of in-house project managers and project deigners, all highly experienced in the material handling industry. We’ll work with you to make sure that your cold storage racking system is the best fit for your operation, installed, and completed on-time and within budget.

We’d appreciate the opportunity to help you further, whether that be more information or a quote. Fill in the contact form on this page or call us at (800) 252-5955 to get in touch with a REB representative.

Share this post:

Share this post:

Submit Your Inquiry

Since 1962

REB has completed more than 100,000 projects in 15 countries (including all 50 states) for more than 20,000 customers across 50 industries, with 70% of customers as repeat buyers.

This is made possible by our team that has more than 300 years of industry experience designing and project managing material handling systems.

Learn more about REB's award winning service.