A Guide to Lighted Picking Systems

Lighted picking systems, utilizing advanced pick to light and put to light technologies, have transformed the landscape of modern warehouses and distribution centers. These systems are designed to enhance order fulfillment processes by increasing accuracy and speed, especially beneficial in operations such as general merchandise retailers or apparel companies. This guide will explore how lighted picking systems work, their benefits, and the various types available to optimize your warehouse operations.

Understanding Lighted Picking Systems

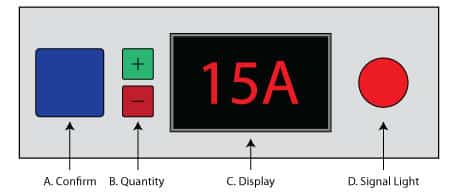

Lighted picking systems incorporate visual aids to streamline the order fulfillment process. Each item or order location within a warehouse is equipped with a lighted numeric or alphanumeric display. This setup typically includes a signal light, an acknowledgment button, and a digital display that shows quantities or messages needed for picking. Some models also feature quantity adjustment buttons or larger displays for full-text instructions, enhancing ease of use and efficiency.

Components of Lighted Picking Systems

-Signal Light: Guides the picker to the correct location, reducing time spent searching for items.

-Acknowledgment Button: Allows operators to confirm the completion of a pick, ensuring order accuracy.

– Digital Display: Provides essential information such as item quantities and pick instructions directly at the point of pick.

Pick to Light Systems

How Pick to Light Works

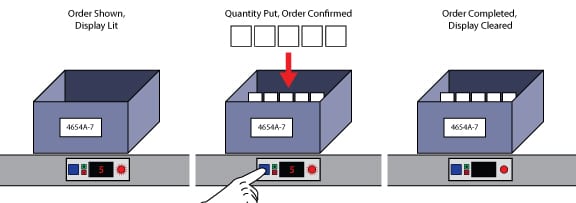

In pick to light systems, operators are directed to item locations through illuminated signals. Upon scanning a barcode associated with an order, the specific locations light up, indicating the items and quantities required. The operator collects the items, confirms each pick, and the light dims to signal completion. This process continues until the entire order is fulfilled.

Benefits and Applications

Pick to light systems are particularly effective in environments where high-speed picking is crucial. They are ideal for team-based order fulfillment strategies such as zone picking. This system not only speeds up the picking process but also reduces errors and enhances productivity and cost-efficiency in each zone.

Put to Light Systems

How Put to Light Works

Put to light systems are designed for efficient order consolidation. The operator scans the items being stocked, and lights indicate the specific bins or containers where each item needs to be placed, along with the required quantities. After placing the items in the correct bins, the operator presses the acknowledgment button at each lighted location to confirm completion.

Ideal Use Cases

Put to light systems are best suited for environments where bulk order fulfillment is common. They are widely used by retailers in industries such as apparel, groceries, convenience foods, sporting goods, and personal care products. These systems allow for rapid and accurate stocking of multiple orders simultaneously.

Technological Advancements and Trends in Lighted Picking

The technology behind lighted picking systems is continuously evolving, making these systems increasingly popular in busy distribution centers where accuracy and speed are paramount. Modern advancements include integrating these systems with warehouse management software (WMS) to further streamline operations and improve data accuracy.

Choosing the Right Lighted Picking System for Your Operation

Selecting the appropriate lighted picking system depends on several factors, including the nature of the inventory, the layout of the distribution center, and the specific operational goals. It is essential to assess both the immediate and long-term benefits of implementing such systems to ensure they align with your operational strategies and growth objectives.

Connect with Industry Experts

To explore how lighted picking systems can optimize your warehouse operations, or to understand which system would best fit your needs, consider reaching out to professionals who specialize in warehouse optimization. Their expertise can guide you through the selection, implementation, and optimization of the right system for your business.

By harnessing the power of lighted picking technologies, warehouses and distribution centers can achieve significant gains in efficiency and accuracy, ensuring they meet the demands of modern commerce more effectively.

Share this post:

Submit Your Inquiry

Since 1962

REB has completed more than 100,000 projects in 15 countries (including all 50 states) for more than 20,000 customers across 50 industries, with 70% of customers as repeat buyers.

This is made possible by our team that has more than 300 years of industry experience designing and project managing material handling systems.

Learn more about REB's award winning service.