When to Use Last-in, First-out Storage (LIFO)

Article Updated: 01/21/2022

Last-in, first-out (LIFO) is a type of inventory management that allows you to remove the most recently placed inventory in a rack system. You would most often use a LIFO rack system for goods with a long shelf life or those held in large quantities.

If you’re interested in first-in, first-out rack options (FIFO), you can view our FIFO rack article.

Last-In, First-Out Rack Options

There are several types of last-in, first-out storage racking options. They are double deep selective pallet rack, drive-in rack and push back rack.

Read below to learn more about each type including how it work, ideal applications, and commonly seen advantages.

Double Deep Selective Pallet Rack

How It Works

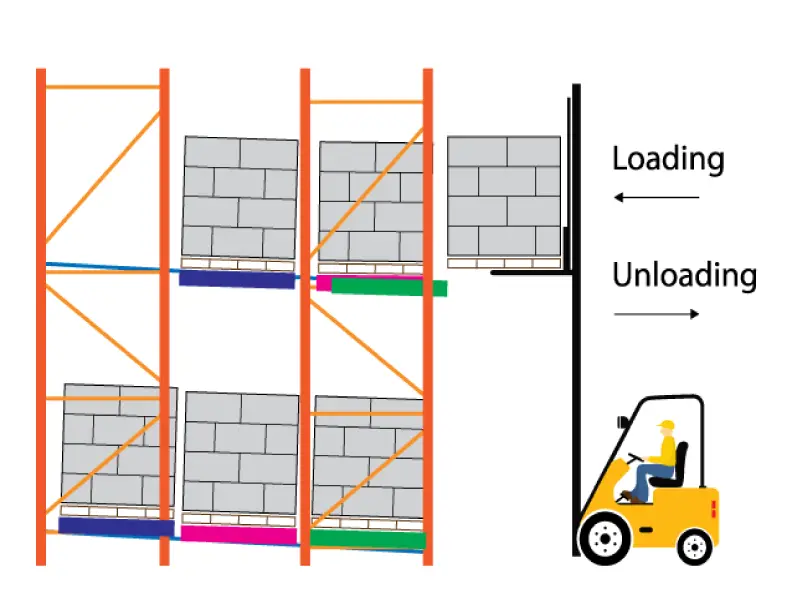

- Pallets are loaded and unloaded from the front via lift truck.

- Enables direct access to all pallets or cartons without needing to move others.

Ideal Uses

- A warehouse or distribution center setting.

- Continuous product circulation.

- Require access to all palletized items simultaneously.

- Storage of retail product, food, and beverage – although can be used to store other products.

- May be used for reserve storage.

Key Features

- Most common racking type.

- Offers high selectivity with lower density.

- Most common bay size 96″ wide x 42″ deep.

Drive-In Rack

How It Works

- Lift trucks load and unload by entering through the front of the system and then back out.

Ideal Uses

- Sorting large quantities of homogeneous product.

- Storing products with long life spans.

- Storing products that require large, one time moves.

Key Features

- Eliminates the need for down-aisle picking aisles.

- Drive-in rack offers higher density than drive through rack.

- Lower selectivity, higher density.

- Can support cooler or freezer storage.

Push Back Rack

How It Works

- The rack supports carts that move along inclined rails.

- Utilizes the warehouse cube to reduce required aisle space and maximize product storage.

Ideal Uses

- Storage of frozen or chilled products.

- Storage of products 2-6 pallets deep.

Key Features

- Variety of configurations available with bay widths that accommodate single-wide or double-wide pallet rows.

- High density storage.

- Rack can be as high as needed.

- Allows access to multiple groups of SKUs simultaneously.

- More efficient picks, each lane can hold a particular SKU.

Your Next Steps for a Last-In, First-Out Storage System

Now that you have a better idea of what a last-in, first-out storage system can offer your warehouse, we’d appreciate the opportunity to help you with the next step. Whether you are certain which system will work best for you or you are in need of more guidance, our experts are ready to assist you.

REB has a talented team of in-house project managers and project designers, all highly experienced in the material handling industry. We’ll work with you to make sure that your system is the best fit for your operation, installed and completed on-time and within budget.

We’d appreciate the opportunity to help you further, whether that be more information or a quote. Fill in the contact form on this page or call us at (800) 252-5955 to get in touch with a REB representative.

Share this post:

Submit Your Inquiry

Since 1962

REB has completed more than 100,000 projects in 15 countries (including all 50 states) for more than 20,000 customers across 50 industries, with 70% of customers as repeat buyers.

This is made possible by our team that has more than 300 years of industry experience designing and project managing material handling systems.

Learn more about REB's award winning service.