FIFO Rack Systems 101: Choosing the Right Racking System

What Does it Mean to be a FIFO Rack System?

First-in, first-out, or FIFO, is a type of inventory management that allows inventory placed into a rack system first to be removed first. FIFO rack systems are ideal for customers requiring rapid stock rotation, have a high turnover rate for inventory, or store items with expiration dates. For example, FIFO food storage applications allows for constant product movement, safeguarding that no inventory spoils or goes to waste.

With a distinct variety of FIFO rack systems, you’re sure to find the FIFO rack option that is right for your warehouse or distribution center.

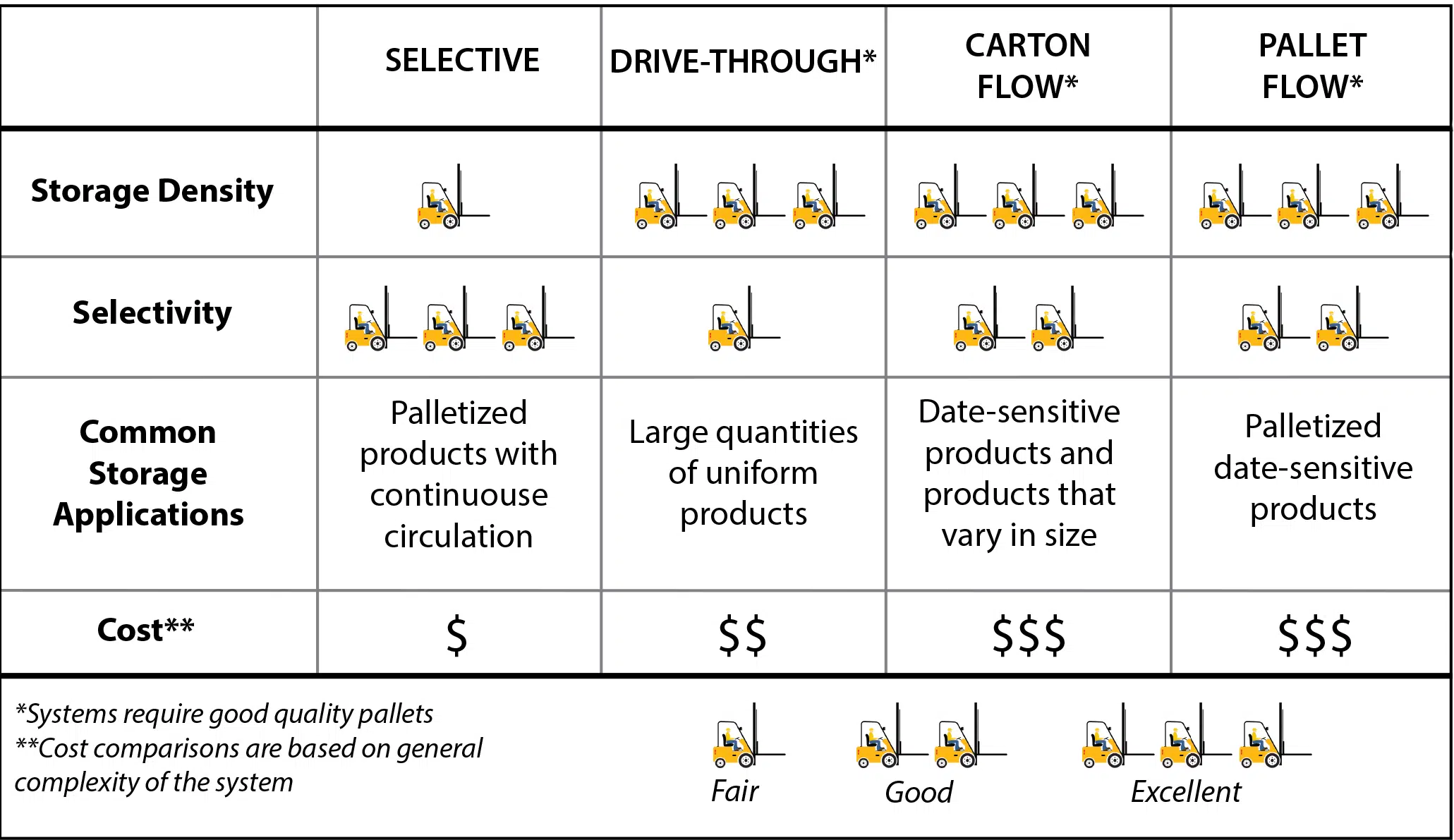

FIFO Rack System Options

Selective Pallet Rack

Selective racking allows direct access to all stored pallets or cartons without the need to move others, making it a highly selective solution. Numerous aisles are required to accommodate this high selectivity. This makes it a lower density option compared to other types of rack systems.

Selective pallet rack is ideal for warehouses with continuous product circulation or that require access to all palletized items simultaneously. Selective pallet rack is a good option for FIFO food storage management.

Drive-Through Rack

Drive-through rack is designed to store pallets on support rails that are attached to uprights and are accessed by a lift truck that drives in to the system with the load elevated to the height of the rail and placed in the selected storage location. This provides high storage density by eliminating picking aisles, but offers low selectivity.

Drive-through racking is ideal for storing large quantities of similar products, products with long life spans, and products that only require large, one-time moves.

Gravity Flow Systems

Gravity flow rack systems include carton flow and pallet flow. They are designed so that rack supports inclined rollers or wheels. This allows products to glide from the back loading aisle to the front picking aisle.

Gravity racks provide excellent volume utilization. Gravity flow can be configured in many different ways. Such as a stand-alone system, integrated with various pallet rack types, or within a multi-level pick module.

Gravity flow systems are ideal for storing materials with expiration dates such as food and beverage, materials that vary in size as well as freezer or cold storage applications. Carton flow rack is also ideal for high volume case-pick and piece-pick applications.

Pallet Flow Rack

Carton Flow Rack

Pallet Runner/Pallet Shuttle Systems

In a pallet runner system, pallets are loaded into the system by a lift truck then transported and placed on the rack by an automated cart. The process of unloading is the same: the cart collects and transports pallets out of the system to the picking position, while an operator moves between the lane and the shipping dock or other destinations. Adding this automated element to a material handling system results in faster pick times and less pick errors compared to static rack systems, since the pallet runner system retrieves the product and has it ready for the driver when they return from the loading dock.

Pallet runners eliminate the need for pick aisles throughout the system, since lift trucks do not need to enter aisles to retrieve product. Therefore, this system provides superior density compared to many rack systems.

There are several ways that a pallet runner system can be set up for FIFO storage. The first option is loading pallets on one end and unloading from the other end. Another option is setting up the system to have bi-directional capability, which allows the option to choose per pick which end should be the picking position. Lastly, the system can be designed to have split lanes. For example, in a 40 deep pallet system, the first 10 can be designed as last-in, first out, while the remaining 30 can be designed as FIFO.

Advantages of FIFO Product Flow

Having a first-in, first-out product flow can be beneficial to many types of operations. Some commonly seen advantages include:

- High selectivity, increasing warehouse productivity.

- High density, improving warehouse space optimization.

- Prevents inventory from becoming outdated.

- Prevents inventory from declining in value.

- Helps ensure that any inventory warranties do not expire.

- Allows for easier tracking of stock, since each lane is generally its own SKU and is therefore highly visible.

Integrating FIFO Racking with Other Storage Solutions

FIFO racking systems can be combined with other types of material handling solutions such as pallet racking, semi-automated or fully automated systems. Tailoring your products and throughput needs in this way will maximize your available storage space and increase efficiency.

The photo in this section shows an example of multiple types of FIFO racking systems integrated together to make a more efficient system. In this example, two-deep pallet flow was included on the ground level for faster-moving products. Two levels of carton flow were integrated with the pallet flow for case picking of items that need replenishment closer to the 1-month range. Five levels of selective rack were included on top for the immediate product replenishment of the carton and pallet flow.

A REB material handling specialist can work with you to understand your products and throughput needs to develop an integrated system that works best for you.

Your Next Steps for a First-In, First-Out Racking System

REB is highly knowledgeable and experienced in designing and installing FIFO rack systems. As a systems integrator, we’ll work with you to provide a turnkey system. From design, products procurement, subcontractor management, install, and permitting support, REB handles it all for you.

REB has a talented team of in-house project managers and project designers, all highly experienced in the material handling industry. We’ll work with you to make sure that your system is the best fit for your operation, installed and completed on-time and within budget.

We’d appreciate the opportunity to help you further, whether that be more information or a quote. Fill in the contact form on this page or call us at (800) 252-5955 to get in touch with a REB representative.

Share this post:

Submit Your Inquiry

Since 1962

REB has completed more than 100,000 projects in 15 countries (including all 50 states) for more than 20,000 customers across 50 industries, with 70% of customers as repeat buyers.

This is made possible by our team that has more than 300 years of industry experience designing and project managing material handling systems.

Learn more about REB's award winning service.