Warehouse Storage Solutions: A Professional Guide

Article Updated: 2/28/2022 Back to Blog

There are a number of warehouse storage solutions out there, and while a couple of these may ‘work’ for your operation, there’s likely one that is the most beneficial. Identifying and utilizing this ideal warehouse storage solution will ensure optimized density and selectivity, increasing efficiency and ultimately profits.

In this article you’ll learn:

- Features, benefits, and ‘how it works’ for warehouse rack systems selective, pallet flow, carton flow, push back, and drive-in/drive-through.

- Features, benefits, and ‘how it works’ for warehouse automation solutions pallet runners, pick-to-light and put-to-light, voice picking, and conveyor systems.

Warehouse Rack Systems Explained

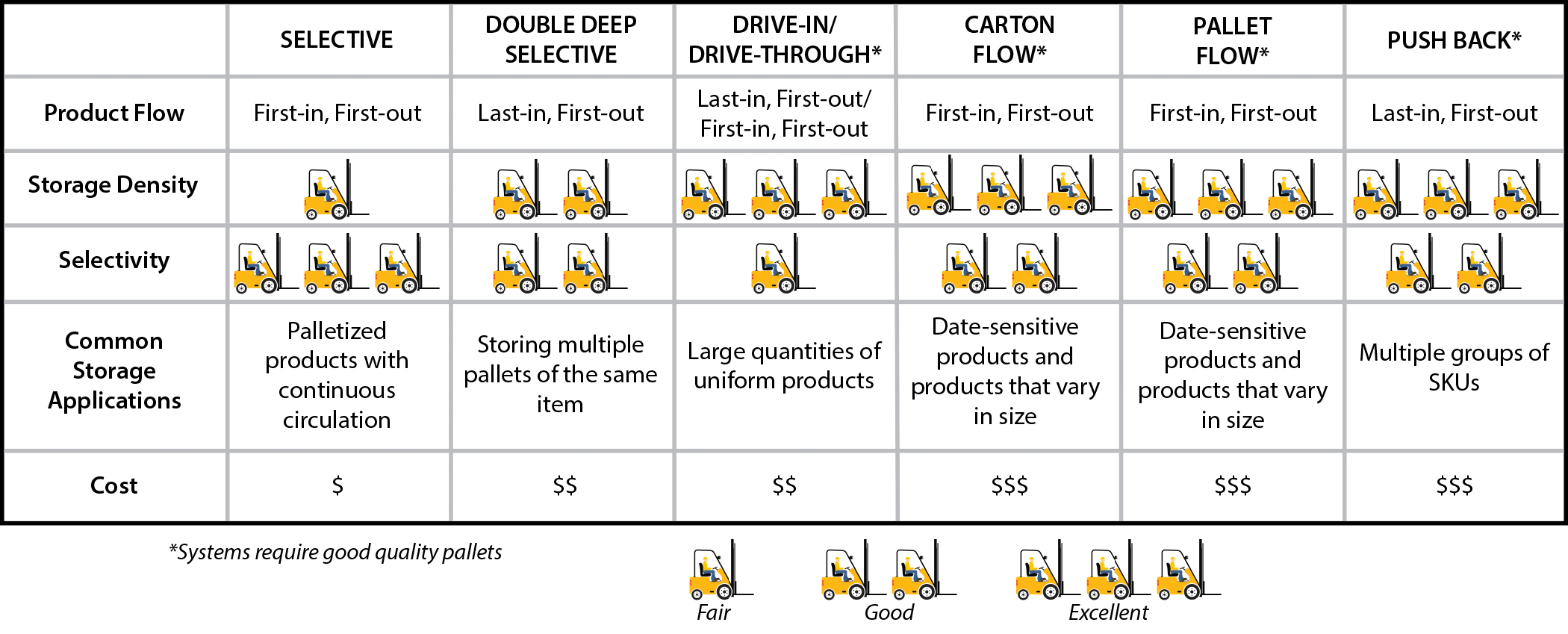

To get started, check out this infographic that details the various features of different types of warehouse storage solutions, including pallet rack and pick modules:

Selective Pallet Rack Overview

Selective pallet rack enables direct access to all stored pallets or cartons without the need to move others, making it a highly selective solution where it is necessary to have a wide variety of products stored.

Numerous aisles are required to accommodate this high selectivity, making it a lower density option compared to other types of rack systems.

Selective rack is ideal for warehouses or distribution centers with continuous product circulation or that require access to all palletized items simultaneously.

Selective rack is for first-in, first-out (FIFO) inventory management. Pallets are loaded and unloaded from the front. Double deep selective rack is also available for a last-in, first-out (LIFO) inventory management option.

Learn more about selective pallet rack.

Pallet Flow Rack Overview

In pallet flow rack systems, rack supports inclined rollers or wheels allowing pallets to glide from the back (loading) aisle to the front (picking) aisle. When the front pallet is unloaded, the next automatically glides into picking position. Brakes can be included for speed control.

Pallet flow systems can be configured up to 12 lanes deep, providing excellent volume utilization and high-density storage.

Pallet flow rack is ideal for date-sensitive products such as food and beverage storage as well as freezer or cold storage applications.

Learn more about pallet flow rack.

Carton Flow Rack Overview

In carton flow rack, the rack supports inclined rollers or wheels allowing cartons to glide from the back (loading) aisle to the front (picking) aisle. Individual lane guides and tilt trays located at the discharge end can be added to allow for easy access into the top of a case or tote for piece-picking.

Carton flow systems provide excellent volume utilization for high volume case pick or piece pick applications. It is ideal for products varying in size, date-sensitive products such as food and beverage storage and freezer or cold storage applications.

Carton flow rack is for first-in, first-out (FIFO) inventory management. Cartons are loaded from the back of the system and glide to the front for picking. When the front carton is unloaded, the next automatically glides into picking position.

Learn more about carton flow rack.

Drive-In & Drive-Through Rack Overview

In drive-in and drive-through racking, pallets are stored on support rails that are attached to uprights and are accessed by a lift truck that drives in to the system with the load elevated to the height of the rail and placed in the selected storage location. This provides high storage density by eliminating picking aisles but offers low selectivity.

Drive-in and drive-through racking systems are ideal for storing large quantities of homogeneous products, products with long life spans or products that require large, one time moves.

Drive-through rack allows a lift truck to enter through both ends of the system for loading and unloading allowing for a FIFO storage option but requiring an additional aisle.

Drive-in rack requires the lift truck to load and unload by entering through the front of the system and then backing out, making it a LIFO option.

Learn more about drive-in and drive-through rack.

Push Back Rack Overview

In push back rack, the rack supports carts that move along inclined rails. Push back systems utilize the warehouse cube to reduce required aisle space and maximize product storage, making it a high-density pallet storage solution.

Push back systems are ideal for warehouse and distribution centers that require access to multiple groups of SKUs simultaneously, as well as freezer and cooler environments.

Push back racking is for last-in, first-out (LIFO) inventory management. Each pallet is loaded from the front of the system on to a cart. Using the next pallet, the first is slowly pushed until it is aligned with the next available cart. When the front pallet is unloaded, the next pallet glides to the front for picking.

Learn more about push back rack.

Warehouse Automation Solutions Explained

Pallet Runners Overview

Pallet runners are semi-automated deep lane storage that delivers the product via a cart that runs on a track within the racking system. The carts can be outfitted to suit a wide variety of pallet designs. The pallet runner can deliver the product at a higher rate and provide more density than typical drive-in racking.

Pallet runners eliminate the need for wider picking aisles, allowing the entire volume of your warehouse to be utilized. Pallet runners are ideal for operations with a high number of pallets that make up a low number of SKU’s,

In a system utilizing pallet runners, pallets are loaded into the system by a lift truck then transported and placed on the rack by an automated cart.

The process of unloading is the same: the cart collects and transports pallets out of the system while an operator moves between the lane and the shipping dock or other destinations.

Learn more about pallet runners.

Pick-to-Light and Put-to-Light Systems Overview

Pick-to-light and put-to-light systems are comprised of lighted displays attached to the pick face of each SKU. Pickers can scan bar codes to be directed to the item location. The message display and indicator light inform the picker of the quantity to be picked or placed (put).

Pick-to-light and put-to-light are ideal for high-density fast mover product picking applications requiring 300-500 lines per man-hour pick rates. Distribution centers that have a team-based approach to order fulfillment, like zone picking, can also benefit from pick-to-light and put-to-light.

Pick-to-light and put-to-light have a relatively low hardware and install cost compared to other automation options, especially when you consider some of the other advantages:

- 99.9% accuracy.

- Shortened order fulfillment cycle times.

- Reduced Labor costs.

- Reduction in picking and placing errors.

- Low Pick-to-Light Hardware and Installation Investment

Learn more about pick-to-light and put-to-light systems

Voice Picking Systems Overview

Voice picking systems enable hands-free, single-touch pick and pack operation. Voice picking can be much more efficient than picking via paper or RF transmitters, since the operator does not have to ‘look down’ to reference their next steps. This results in higher accuracy as well as seconds saved with each step the operator must make (which quickly adds up!).

With voice picking, the operator is directed by the voice command via a headset for each step in the process. The voice command can be customized to each company’s specific operation.

For example, the voice command will tell the operator that they are to ‘cart pick’ (as opposed to fork truck pick). The operator lets the voice command know once they’re at the cart pick location. The voice command will then direct them to put box size A in position 1, box size C in position 2, and box size D in position 3 on the cart. The operator will confirm once completed. The voice command will then direct them to go to the pick locations for each box, providing the optimized pick path.

Benefits of voice picking include:

- Increased pick accuracy – up to 99.99%!

- Increased pick volume per worker.

- Increased accuracy in picking, with a reduction in repeat work.

- Can eliminate packing operators.

- Integration of picking and fulfillment processes, yielding greater efficiency from pick to shipment

Learn more about voice picking systems

Vertical Lift Module System Overview

A vertical lift module, commonly referred to as a VLM, is an enclosed systems of vertically arranged trays stored in both the front and rear with an extractor device operating in the center.

In a vertical lift module, trays are stored using the least amount of space, ensuring maximum storage density within the VLM. This is accomplished by the system scanning the height of the products going back into the system and placing that tray in the ideal storage location slot.

The vertical lift module automatically delivers trays with the stored items to an access window with a push of a button or a scan of a barcode.

For example, picker scans a barcode or pushes a button on the vertical lift module. Then the vertical lift module retrieves the product and presents the tray via the access window. A laser pointer or LED screen will then identify the specific pick location on the tray. The operator will confirm once thetask is completed. The VLM repeats this action for the next item on the scanned list.

Benefits of a vertical lift module include:

- Increased pick accuracy – up to 99.99%!

- Reduced labor costs

- Eliminates dwell time

- Saves 75-85% of floor space

- Eliminates Shrinkage

- Increased pick speed

Learn more about vertical lift module systems

Conveyor Systems Overview

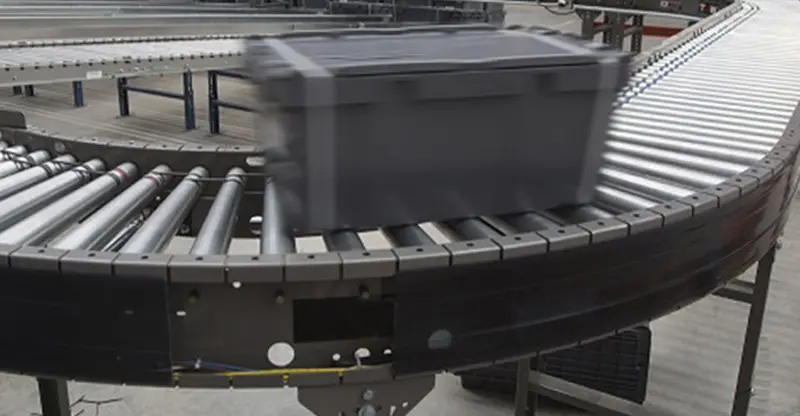

Conveyors allow for products to move from location to location within your warehouse. There are many options when it comes to conveyor types, so finding the correct conveyor type for your warehouse is important. There are three main types of conveyors to consider – transportation, accumulation, and sortation.

Transportation Conveyors

Transportation conveyors move pallets or cartons from point A to point B. Transportation conveyor options are available to accommodate requirements such as desired speed and product handling procedures. Transportation conveyors include gravity, belt, and live roller conveyors.

Learn more about transportation conveyors.

Accumulation Conveyors

Accumulation conveyors move loads from point A to point B, allowing them to accumulate when necessary to allow time for equipment or other material handling resources to become available down the line. Accumulation conveyors include zero pressure, zero contact, and minimum contact conveyors.

Learn more about accumulation conveyors.

Sortation Conveyors

Sortation conveyors are used to direct products from one conveyor line to another. These are tailored to each operation to properly identify, track and transport products to expedite the order fulfillment process. Sortation conveyors include shoe sorter, pop-up wheel, right angle transfers, arm (or pusher) style, narrow belt, tilt tray (or loop sorter), and cross-belt.

Learn more about sortation conveyors.

Looking for a Warehouse Storage Solutions that Works for You?

Now that you have a better understanding of warehouse storage solutions, we’d appreciate the opportunity to help you further, whether that be more information or a quote. Fill in the contact form or call (800) 252-5955 to get in touch with a REB representative.

REB Storage Systems offers all racking and automation options mentioned in this article. We know your options and will make sure your system is the best fit for your SKU profiles, space, and growth projections. We work with you to provide a turnkey system. From design, products procurement, subcontractor management, install, and permitting support, REB handles it all for you.

REB has 17 in-house project managers and designers, all highly experienced in the material handling industry. These people know this industry inside and out.

So don’t settle for an inadequate material handling system. Instead, call us or fill out the contact form on this page and get an awesomely efficient material handling system.

Share this post:

Submit Your Inquiry

Since 1962

REB has completed more than 100,000 projects in 15 countries (including all 50 states) for more than 20,000 customers across 50 industries, with 70% of customers as repeat buyers.

This is made possible by our team that has more than 300 years of industry experience designing and project managing material handling systems.

Learn more about REB's award winning service.