Material Handling Systems: 4 Types, Uses & Choosing Yours

materials handling, noun: the loading, unloading, and movement of goods, as within a factory or warehouse, especially by the aid of mechanical devices.(1)

Welcome to Material Handling 101: The Ultimate Operations Guide to Material Handling Systems. If you found our comprehensive guide, chances are you are doing research into the fundamentals of material handling systems, which types of material handling systems would best benefit your business, or best practices to help optimize your operation. As experienced material handling integrators, we thought we’d share our knowledge with you. In this guide, we’ll cover the following topics:

- Introduction to Material Handling

- Benefits of Optimized Material Handling

- Material Handling Best Practices

- Types of Material Handling Systems

- How to Choose The Right Material Handling System

- Types of Material Handling Equipment

- Future-Proofing Your Material Handling Operation

Introduction to Material Handling

Put simply, material handling is the safe and efficient movement, storage, control, and protection of materials throughout the supply chain. Material handling plays a crucial role in various industries, including manufacturing, warehousing, distribution, and logistics. The wide range of activities encompassed by material handling includes loading and unloading, transportation, inventory management, order fulfillment, and packaging.

Effective material handling systems and warehouse storage solutions are essential for streamlining operations, reducing costs, and ensuring smooth workflows.

The Importance of Material Handling

Efficient material handling systems are vital for several reasons. Firstly, it improves overall operational efficiency by reducing downtime, minimizing product damage, and optimizing workflows. Implementing material handling best practices can also enhance workplace safety by utilizing proper equipment, training, and protocols. Lastly, it contributes to cost savings by eliminating waste, improving inventory management, and minimizing operational expenses.

The 4 Fundamental Principles of Material Handling

- Planning: Proper planning by material handling systems integrators ensures smooth material flow, optimal space utilization, and efficient use of resources. It involves analyzing material handling requirements, evaluating existing systems, and designing layouts that maximize productivity.

- Standardization: Establishing standardized processes and equipment helps improve efficiency, minimize errors, and simplify training. Standardization also enables better coordination between different departments and enhances overall productivity.

- Ergonomics: Considering ergonomics in material handling design helps reduce the risk of injuries and work-related musculoskeletal disorders among employees. Ergonomically designed workstations, tools, and equipment promote worker safety and comfort, leading to increased productivity.

- Automation: Implementing material handling automation technologies such as robotics, conveyors, and automated guided vehicles (AGVs) can significantly improve material handling efficiency, reduce labor costs, and enhance overall throughput.

Talk to an Experienced Material Handling Systems Integrator Today

Benefits of Optimized Material Handling

Optimizing your material handling operations brings several significant benefits:

Prevents Workplace Accidents

By implementing proper safety measures and equipment, you can significantly reduce workplace accidents and injuries. This not only protects your employees but also minimizes downtime and associated costs.

Improves Employee Satisfaction

Efficient material handling systems and equipment simplify tasks and reduce manual labor for employees. This improves their overall job satisfaction and morale, leading to higher productivity and retention rates.

Increases Productivity and Efficiency

Optimized material handling streamlines processes, reduces cycle times, and eliminates unnecessary steps or movements. This results in increased productivity, faster order fulfillment, and improved customer satisfaction.

Saves You Money

Efficient material handling minimizes waste, reduces operational costs, and improves inventory management. By optimizing storage space, eliminating product damage, and enhancing workflow efficiency, you can save money in the long run.

Material Handling Best Practices

Safety in Material Handling Operations: Safety is of paramount importance in material handling operations. By implementing proper safety measures, you can create a safe working environment for your employees. For example, conducting regular safety training programs with employees, performing regular safety inspections of material handling systems, enforcing the use of personal protective equipment (PPE), and implementing clear signage and safety protocols can significantly reduce workplace incidents.

Sustainable Material Handling Practices: In today’s environmentally conscious world, adopting sustainable material handling practices is crucial. These practices include reducing energy consumption, optimizing transportation routes, recycling packaging materials, and minimizing waste generation. Implementing sustainable practices not only helps protect the environment but also lowers costs and enhances your company’s reputation.

Preventive Maintenance for Material Handling Equipment: Regular preventive maintenance is essential to keep material handling equipment in optimal condition. By adhering to manufacturer-recommended maintenance schedules, conducting inspections, and promptly addressing repairs, you can minimize equipment downtime, extend its lifespan, and prevent costly breakdowns.

Continuous Improvement in Material Handling Processes: Embracing a culture of continuous improvement is vital for enhancing material handling processes. Encourage your employees to provide feedback on your material handling solutions and suggestions for process improvement. Regularly analyze workflows, identify bottlenecks, and implement changes that streamline operations and increase efficiency.

Efficient Material Storage and Retrieval: Efficiency is the name of the game when structuring your material handling system. Efficient logistics are a necessity when reacting to and planning for customer and warehouse requirements. Because inbound inventory’s material handling processes are just important as outbound’s processes.

Material handling process has four dimensions that impact efficient product flow through your warehouse: Movement, Time, Quantity, Space

-

- Movement: moving product from Receiving to Outgoing

-

- >>Small scale example: using a fork truck to move inventory from storage onto a truck for shipment <<

-

- >>Large scale example: using a conveyor system to move inventory around a 100,000 sq ft distribution center <<

- Time: how long products live in storage, receipt of inventory-to-shipment time frame

- Quantity: how much product can be storage in the allotted space

- Space: how much space is allotted or available

Talk to an Experienced Material Handling Systems Integrator Today

Types of Material Handling Systems

A material handling system is at the core of a distribution operation. Selecting the right material handling system enables efficient storage and retrieval. A material handling system is not one size fits all, but instead is based on your specific needs that includes SKU profiles, warehouse layout, and desired distribution operations. A material handling system can integrate several solutions such as pallet racks, automated or semi-automated systems, mezzanines, and shelving systems.

Read below to learn more about common types of material handling systems.

Racking Systems

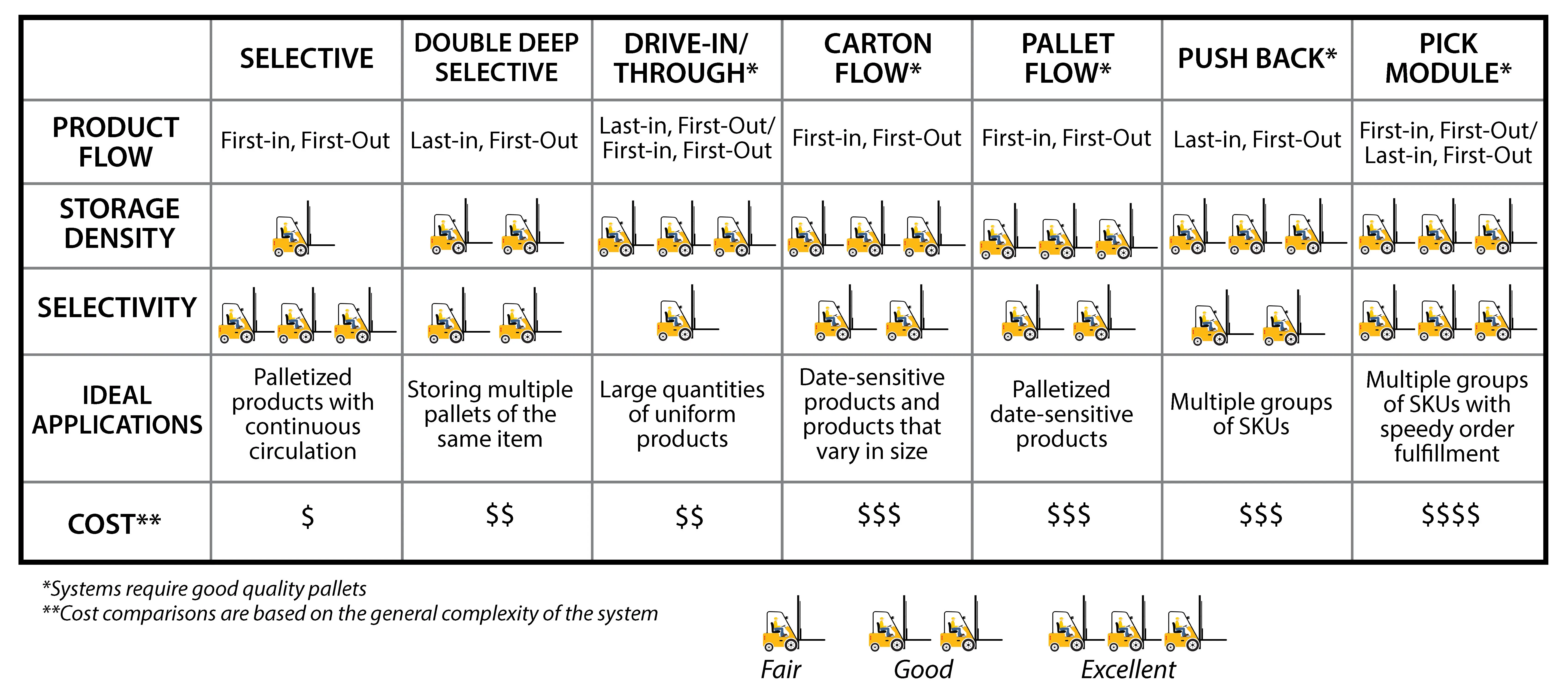

Racking systems are versatile solutions for storing large quantities of materials. Racking Systems include selective rack, push back rack, pallet flow rack, carton flow rack, cantilever rack, and drive-in and drive-through rack.

Each type of racking system offers its own benefits within an operation and is ideal for different types of operational characteristics. Additionally, more than one type of rack system can be integrated within one operation to provide optimal efficiency.

Learn more about Racking Systems

Automation Systems

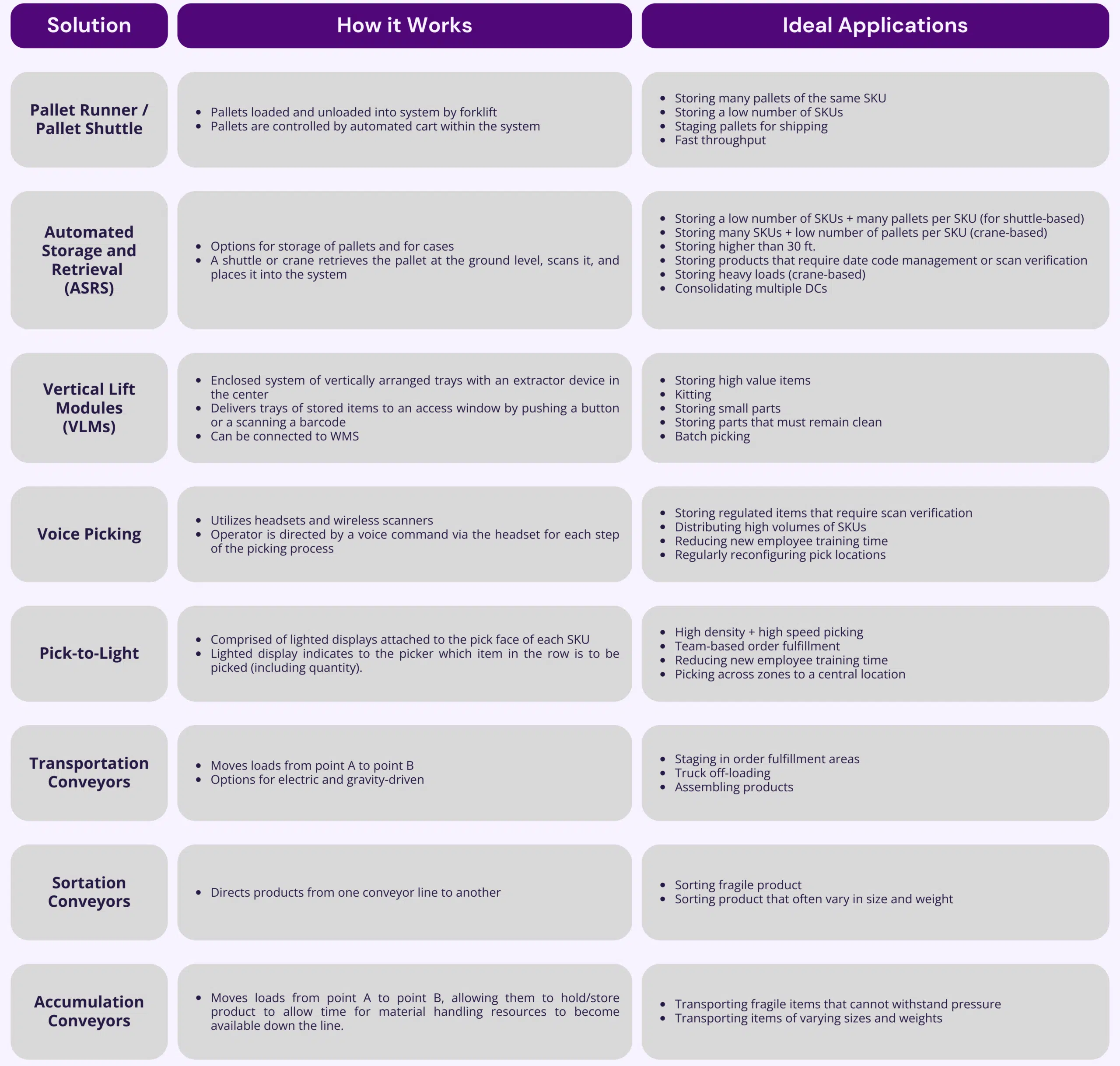

Material handling automation systems significantly enhance material handling efficiency. Options for automated and semi-automated systems include conveyor systems, automated storage and retrieval systems (Unit Load AS/RS & Mini Load AS/RS), pallet runners, vertical lift modules (VLMs), voice picking system, and pick-to-light & put-to-light. Which automated system is right for you depends on several factors, including SKU profiles and desired throughput. Automated systems are often integrated into an overall material handling operation that can include other systems, such as pallet racking.

Learn more about Material Handling Automation Systems

Shelving Systems

Shelving systems can be ideal for storing lighter, unpalletized items. Shelving Systems options include boltless rivet shelving, wire shelving, and mobile shelving. Boltless rivet shelving provides flexibility and easy assembly, while wire shelving offers excellent visibility and airflow. Mobile shelving systems maximize storage capacity by compacting shelves on tracks, optimizing space utilization.

Learn more about Shelving Systems

Pick Module Systems

A pick module system is a combination of material handling systems to create a comprehensive solution. Pick modules can include racking systems, automation systems, shelving systems, mezzanines, and order-picking technologies all uniquely designed to streamline the order fulfillment process.

When implemented correctly, pick module systems efficiently organize and sequence products for picking and packing. Pick modules improve picking accuracy, reduce labor costs, and enhance order fulfillment speed.

Learn More About Pick Module Systems

How to Choose The Right Material Handling System

(Consolidate content, images & links found on https://rebstorage.com/material-handling-system-guide/ / then set redirect after publishing this updated blog)

Whether your operation requires one type of pallet racking or a complex pick module will depend on several factors including SKU profiles, space restrictions, and desired picking practices. To achieve the best material handling system for your operation, it’s essential to have a professional material handling systems integrator assess your operation and provide you with design options. However, we’ve put together four steps that will help you better understand what may be best for you.

1. Determine Your Warehouse Layout

From the point you receive merchandise to the point it’s shipped to the customer, it is important to think about the most efficient way to direct product flow. Three layouts to consider are U-shaped, I-shaped, and L-shaped. Features include:

U-shaped Layouts

- Most common

- Shipping and receiving docks are located next to each other.

- Offers shared utilization of dock resources (personnel, equipment)

- High cross-docking capability, minimizing product handling.

L-shaped and I-shaped Layouts (also known as through flow)

- Shipping and receiving docks are located on different sides of the building.

- Provide heightened security due to the separate “in” and “out” areas.

- Typically provide larger sorting and staging areas for shipping and receiving.

- Provide isolated monitoring of shipping and receiving areas.

2. Assess your inventory to determine which type(s) of racking suits it best.

In order to maximize the benefits of your warehouse, you must understand the characteristics of all the products that are to be stored. To maximize your operation, the product flow, density, and selectivity of your material handling system should align with available storage space and inventory characteristics.

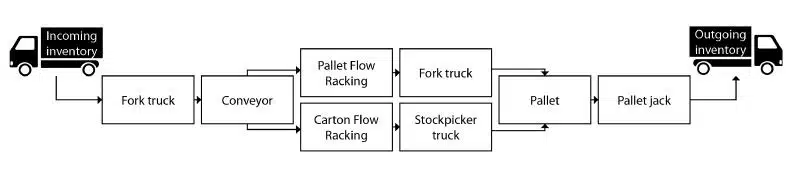

Often, warehouses that store multiple types of products will benefit from integrating more than one type of racking. For example, pallet flow rack can be used for pallets of products that have a high-turnover rate, while selective rack can be used for extra pallets of products to replenish the pallet flow rack.

Selective – Drive-in/Drive-through – Carton Flow – Pallet Flow – Push Back

3. Determine if Automation is a Viable Option

Adding automated or semi-automated material handling systems to your operation can reduce handling costs, increase throughput, and ultimately increase profits. There are many automation options available. Below is an overview of common types of automated and semi-automated systems.

Types of Material Handling Equipment

The correct implementation of material handling equipment is essential for efficient and safe storage, movement, and protection of goods during the manufacturing, distribution, consumption, and disposal processes. Let’s explore some common types of material handling equipment:

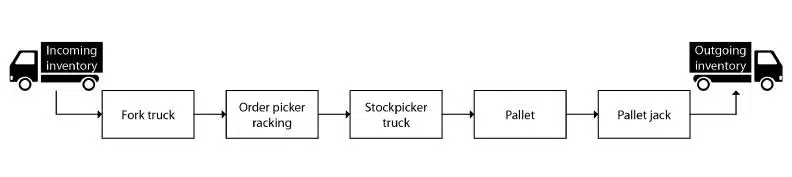

Picking and Transportation Equipment

There are several types of material handling equipment that assists pickers in the safe and efficient transport of products throughout a warehouse. Forklifts are used to both pick and place pallets to and from a pallet rack system or semi-automated system. Pallet jacks are ideal for transporting pallets once they have been picked or transported off a truck.

Wheeled carts assist in expediting the transport of cartons, totes, or bins and can be customized to fit most sizes of containers. Carts can also be purchased with totes for easier picking and organizing of shipments.

Retractable conveyors are another useful option for transporting items from point A to point B. These conveyors are mobile, meaning they are able to easily be retracted and relocated anywhere needed. Retractable conveyors are often used for loading and unloading items on trucks.

Storage Products

The most common material handling products used for storage are containers, bins, and totes. These are available in numerous sizes and options. Options include attached lids, stackable, nestable, titled front for easy viewing of items, and dividers.

Safety Products

Safety products are used to protect both materials and employees. Safety barriers and guards prevent accidents by restricting access to hazardous areas. Column guards, end of row protection, and down aisle protection is used to lessen the damage to a rack system by forklift impact. Frame extensions can be installed to the top of each upright frame to prevent materials from falling off the top beam level.

Talk to a Material Handling Expert Today

Future-Proofing Your Material Handling Operation

When planning your material handling system layout, you should avoid only planning for the present. Futureproofing your material handling system ensures that your operations can grow your business, instead of being a barrier holding you back. To ensure long-term success and adaptability in an ever-evolving landscape, there are several key strategies to implement.

Firstly, embracing technology advancements is paramount. Stay updated on emerging technologies such as automation systems, robotics, and data analytics. These innovations can streamline processes, improve efficiency, and provide valuable insights into operations. By investing in scalable and flexible technologies, you can future-proof your material handling operation and easily adapt to changing business needs.

Secondly, prioritize employee training and development. Equip your workforce with the necessary skills to leverage new technologies and handle evolving challenges. Stay ahead of industry trends and provide ongoing training programs that promote a culture of continuous improvement. This not only enhances employee satisfaction but also ensures that your team is prepared to tackle future challenges head-on. Additionally, fostering a culture of innovation and encouraging employees to share their ideas and insights can lead to creative solutions and improvements in the material handling operation.

Conclusion

Whether you are new to the field or looking to enhance your existing material handling operations, this guide will provide valuable insights and actionable tips to help you improve efficiency, safety, and productivity.

Material handling is much more than the handling of inventory. It’s the movement, protection, storage and control of materials and products throughout their lifespan of manufacturing, warehousing, distribution, consumption, and disposal. Material handling encompasses a range of components to keep the supply chain running. This includes a variety of equipment types (manual, semi-automated, and automated) and systems (single-level storage, multi-level storage, conveyors, etc.).

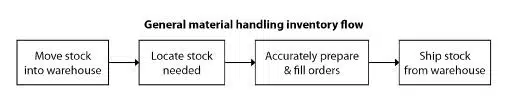

Material handling products improve efficiency by making the logistics system respond quickly and effectively to plant and customer requirements. For efficient movement of goods into the warehouse, locating stock, accurately filling orders, and rapidly preparing orders for shipment to customers. Materials handling is very important to outbound logistics. In inbound logistics terms, materials handling serves company plants in the same way. Material handling systems integrators need to integrate materials handling requirements not only for the company’s departmental needs, but also for meeting their customers’ needs.

At REB Storage Systems International, we pride ourselves on matching the right product to the customer’s needs. The efficiency of your racking is of the highest importance when considering your material handling needs. Firstly, we have a team of project design experts in material handling available to answer any questions you may have about your warehouse or distribution center material handling processes. So, we are here to advise and aid you in regard to what materials you will require to make your workday easier. And with the assistance or our Experienced Sales team, we are ready to provide you with friendly, personalized support.

Contact one of our experts at 773-252-0400 or info@rebstorage.com to find out what material handling equipment you should use for your operation.

Sources:

https://www.mhi.org/fundamentals/material-handling

https://en.wikipedia.org/wiki/Material_handling

http://dictionary.reference.com/browse/materials-handling

https://www2.isye.gatech.edu/~jjb/wh/book/editions/wh-sci-0.96.pdf

Share this post:

Submit Your Inquiry

Since 1962

REB has completed more than 100,000 projects in 15 countries (including all 50 states) for more than 20,000 customers across 50 industries, with 70% of customers as repeat buyers.

This is made possible by our team that has more than 300 years of industry experience designing and project managing material handling systems.

Learn more about REB's award winning service.