Material Handling Systems Integrators: What We Do As Full-Service Integrators

The Role of Material Handling Integrators: Your Partner in Empowering Operations

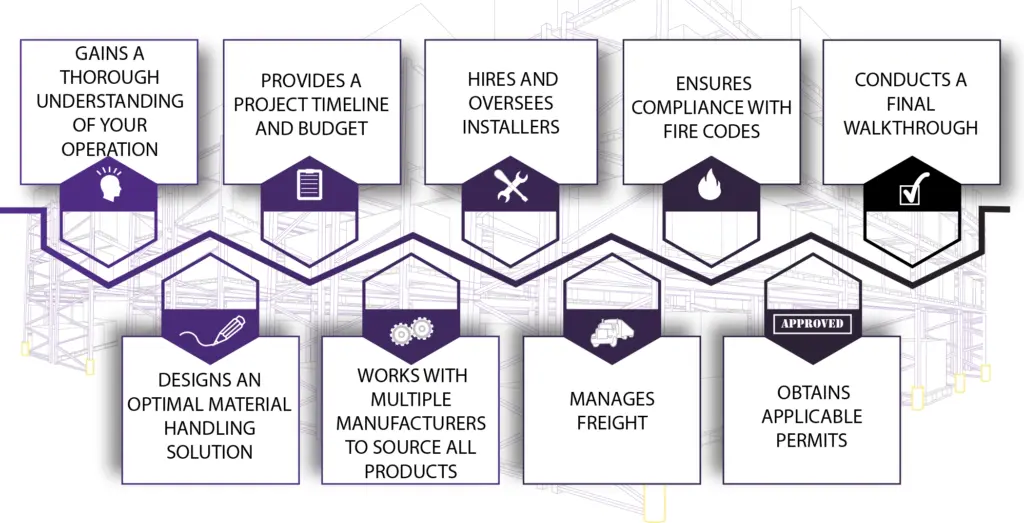

A material handling systems integrator, such as REB Storage Systems, works collaboratively with the client to design and implement an optimized material handling system. This includes providing services such as design, permitting support, installation and project management to deliver a complete system on time and within budget.

The integrator will hire and manage skilled onsite personnel (installers, etc.), but will be the only point of contact for the client. By being the single point of contact throughout each phase of a project, a material handling integrator is accountable for any unplanned disruptions. An example of an unplanned disruption could be if the installers receive a shipment that is short on material. The integrator would be the point of contact to resolve the issue, allowing the client to focus on ongoing company operations.

Additionally, the integrator works behind the scenes to answer any questions the subcontractors have which eliminates the need for them to contact the client directly. This is a beneficial factor of working with an integrator because it helps the overall project run seamlessly with minimum disruptions for the client.

Once the system is installed, an integrator conducts a final walk-through to ensure everything within the system is satisfactory.

Benefits of Using a Material Handling System Integrator

How Material Handling Integrators Improve Efficiency

A major advantage of working with a material handling system integrator is that they have access to many types of material handling solutions via many different vendors. Because of this, material handling integrators can analyze a company’s operations and identify areas for improvement such as bottlenecks, inefficient workflows, or outdated equipment, through the lens of many solutions, instead of being limited to only one manufacturer. By optimizing the flow of materials in this way, integrators can streamline processes, reduce labor costs, and increase productivity. One study by the Material Handling Institute even found that companies implementing material handling systems reported an average 20% increase in throughput.

Additionally, they can recommend and install state-of-the-art technologies, such as automated storage and retrieval systems (AS/RS) and conveyor systems, to further enhance efficiency. Integrators also provide training and support to ensure that the new systems are properly utilized and maintained.

With their expertise and solutions, material handling integrators can significantly improve a company’s overall efficiency, leading to cost savings and a competitive advantage. One such potential cost savings can come from identifying ways in which the client can reduce energy consumption. For example, the U.S. Department of Energy reports that automated conveyor systems can reduce energy consumption by up to 50% compared to traditional methods.

Supply Chain Optimization and Material Handling Integrators

Supply chain optimization is crucial for businesses to remain competitive and meet customer demands. Material handling integrators play a vital role in this process by streamlining the movement of goods throughout the supply chain.

They accomplish this by designing and implementing efficient material handling systems within warehouses and distribution centers, reducing labor costs and increasing throughput. By collaborating with material handling integrators, businesses can achieve a more efficient and responsive supply chain, leading to improved customer satisfaction, reduced costs, and increased profitability. A study by Deloitte found that companies implementing automation reported an average return on investment of 21% within two years.

Material Handling Systems Integrator Services That Can Help Your Business

Material handling systems integrators, like REB Storage Systems, are effective in optimizing warehouse and distribution center operations. Their role extends beyond mere equipment suppliers; they are strategic partners that enhance efficiency, safety, and scalability. Here’s a detailed look at how they contribute to each facet of your business:

Material Handling System Design

The design phase of a material handling system is critical to the success and efficiency of warehouse and distribution center operations. Here’s an overview of how material handling systems integrators design the best system for your business.

Comprehensive Needs Analysis: The first step in effective material handling and warehouse design is conducting an analysis of the business’s needs. This includes evaluating the layout of the space, understanding the characteristics of the inventory, and considering the material handling equipment currently in use. A thorough needs analysis ensures that the proposed system addresses all operational requirements and constraints.

Customized Solution Development: Based on the needs analysis, a customized solution is developed that addresses the unique challenges and goals of the operation. This solution should consider factors such as budget constraints, desired throughput rates, and future scalability. Offering alternative solutions can also provide flexibility, allowing businesses to choose an option that best fits their immediate and long-term needs.

Compliance with Codes and Regulations: Ensuring that the design meets local and federal codes and regulations is essential for the safety and legality of the installation. Compliance with these codes ensures the safety of the employees working within the facility.

Utilization of Advanced Design Tools: Employing advanced design tools, such as Computer Aided Design (CAD) software, is a best practice that allows for the creation of detailed and accurate representations of the proposed system. CAD drawings facilitate the review and modification of designs, enabling stakeholders to visualize the system and make informed decisions before implementation begins.

Collaboration and Communication: Effective collaboration and communication among all stakeholders, including customers, vendors, and contractors are crucial throughout the design process. Regular updates and discussions ensure that everyone has a clear understanding of the project scope, timeline, and expectations, leading to a more streamlined and successful project outcome.

Regular Review and Adaptation: The warehouse design phase should include regular reviews and adaptations based on feedback from all stakeholders. This flexibility allows for adjustments to be made in response to new information or changes in project scope, ensuring that the final design is as effective and efficient as possible.

Check out this Pick Module warehouse design case study to learn more about our process!

Project Management

A critical aspect of any material handling integrator’s approach to project management in rack system projects is the emphasis on proper planning and communication. This foundational principle ensures the successful completion of every project they undertake. Here’s what will make a material handling integrator excel for your project:

Comprehensive Planning: Project managers start by obtaining commitments on lead times for all materials required for the project. This initial step is crucial for setting realistic expectations and timelines.

Detailed Scheduling: With the information on lead times, a detailed project schedule is developed. This schedule highlights all critical milestones and establishes a firm completion date. Such meticulous scheduling is vital for the smooth progression of the project.

Stakeholder Communication: Because it’s crucial to keep all stakeholders informed, the project schedule and any updates are communicated to customers, vendors, contractors, building officials, and internal resources as necessary. This ensures that everyone involved has a clear understanding of the project scope, timeline, and expectations.

Regular Project Updates: We’ve found that providing regular updates both internally and with the customer are important for a few reasons. These updates are essential for monitoring progress, identifying potential delays early, and making necessary adjustments to the schedule.

By prioritizing planning and communication, REB ensures that each project is completed on time, within budget, and to the satisfaction of all stakeholders.

Material Handling System Installation

The installation of rack, shelving, and automation systems is a critical phase in setting up efficient warehouse storage solutions. A well-executed installation not only ensures the optimal use of space but also enhances safety and operational efficiency. Here are the best practices for rack and conveyor installation:

Project Support and Coordination: Comprehensive project support is essential for a smooth installation process. A team of experienced project managers should coordinate the efforts of all subcontractors involved, ensuring that every aspect of the project is aligned and completed on schedule.

Racking System Removal and Relocation Services: In addition to new installations, the ability to efficiently remove or relocate existing racking systems is important for those moving or expanding operations to a new building. A systematic approach to determining the new layout, what rack components can be reused in the new system, developing a detailed removal and relocation plan, and executing it flawlessly is crucial for minimizing downtime and maintaining operational continuity.

Compliance and Safety: Ensuring that the installation complies with all relevant building codes, load applications, rack configuration drawings, and rack component manufacturer’s requirements is paramount. This not only involves the physical installation of the material handling system but also includes the strategic planning of the layout to optimize space utilization and ensure safe operation for warehouse staff.

The installation phase is critical and requires meticulous planning and execution. Integrators ensure that the installation of racks, conveyors, and other systems is performed safely and in compliance with product specifications and local codes. REB’s installation teams are skilled at minimizing downtime and disruptions, allowing your operations to continue running as smoothly as possible during upgrades or installations.

Check out this case study about how we relocated and installed a selective rack system!

Permitting Support

Leveraging the support services of companies that specialize in rack system permitting can alleviate the burden on businesses. These services have the experience and knowledge to navigate the permitting process efficiently, ensuring that all regulatory requirements are met and that the project remains on schedule. Here are the best practices for material handling system permitting support:

Research and Compliance: The first step in the permitting process involves thorough research of the specific requirements for the facility’s location and system type. This includes understanding the building construction type, sprinkler requirements, zoning laws, and occupancy classifications. Ensuring that the storage system design complies with these regulations is crucial for smooth permit approval.

Engineering Expertise: Utilizing the expertise of licensed engineers in our network is essential for preparing and reviewing all necessary documentation for the permit application. This includes detailed drawings, bills of material, and calculation drawings. Having these documents prepared and stamped by the proper licensed engineer demonstrates compliance with industry standards and regulatory requirements, facilitating the approval process.

Proactive Coordination: Proactively coordinating with local building officials and inspectors can significantly streamline the permitting process. Establishing open lines of communication ensures that any concerns or requirements from the authorities are addressed promptly, reducing the likelihood of delays.

Documentation and Record-Keeping: Maintaining comprehensive records of all communications, submissions, and approvals throughout the permitting process is vital. This not only helps in keeping the project on track but also provides a clear audit trail that can be useful for future reference or in case of any disputes.

Check out this case study where permitting support was crucial to the success of the project!

4 Factors to Look for in a Material Handling Integrator

Experience and Expertise

Look for an integrator with extensive experience in your industry and handling the specific types of materials and processes involved in your operations. Ensure they have a proven track record of successful implementations.

Breadth of Solutions

Evaluate if the integrator has a broad range of material handling solutions and technologies in their portfolio. This allows them to provide unbiased recommendations tailored to your unique needs rather than being limited to specific products or brands.

Project Management Capabilities

A skilled integrator should have strong project management capabilities to coordinate all aspects of system design, installation, and commissioning. Look for an integrator that can dedicate a stable team to your project from start to finish.

Post-Installation Support

Inquire about the integrator’s post-installation support services, such as training, maintenance, and system upgrades. A reliable integrator should offer comprehensive support to ensure your system operates efficiently over its lifetime and be a partner to your business as it grows.

End-to-End Solutions with REB’s Full-Service Material Integrators

REB Storage Systems is a material handling system integrator with extensive experience with all types of systems, including racking, shelving, and automation. We have extensive networks of manufacturers and installation subcontractors to provide solutions with flexible lead times. REB maintains extensive project design and project management departments across the US with over 500 years of combined experience, delivering turn-key systems customized to any requirement.

At REB, we look at each project as unique. While many have similarities for which we are able to leverage our experience and knowledge, each client has unique needs that must be met. We’d appreciate the opportunity to help you further, whether that be more information or a quote. Fill in the contact form on this page or call us at (800) 252-5955 to get in touch with a REB representative.

Share this post:

Submit Your Inquiry

Since 1962

REB has completed more than 100,000 projects in 15 countries (including all 50 states) for more than 20,000 customers across 50 industries, with 70% of customers as repeat buyers.

This is made possible by our team that has more than 300 years of industry experience designing and project managing material handling systems.

Learn more about REB's award winning service.