Pallet Flow Racking vs. Push Back Racking: Which Is Idea for Your Operation?

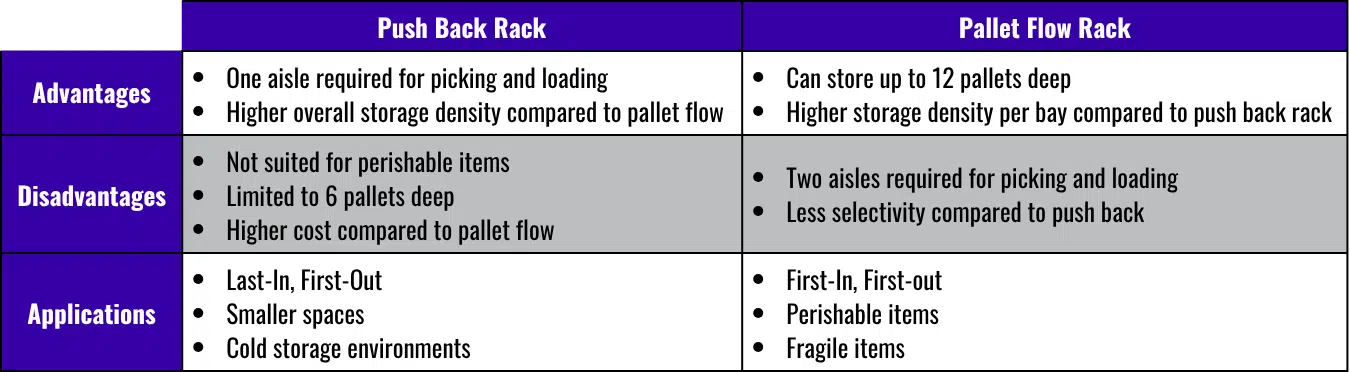

Pallet flow racking and push back racking are two of the most used rack system types in a distribution center, and for good reason: both systems provide excellent space utilization and have unique attributes for storing and distributing compared to other types of pallet rack.

Although each system has similar benefits, these benefits are only effective if used for the right application. Factors to consider include product characteristics, picking processes, and space availability.

Read this article to find out which type is best for you!

How Push Back Rack Systems Work

Push back racks are last-in, first-out gravity storage systems that use carts that are pushed along inclined rails. This rack system provides high-density as it only requires one aisle for picking and allows access to multiple groups of SKUs.

Each pallet is loaded from the front of the system on to a cart. To load the next pallet, you must carefully push the first pallet position with the pallet you are attempting to store next.

When the next pallet is loaded, it slowly pushes the previous pallet back to allow for the new pallet to align with the next available cart. When the front pallet is unloaded, the pallet behind glides to the front for picking.

Watch the video below to learn more about how push back systems work.

How Pallet Flow Rack Systems Work

Pallet flow racks are gravity flow storage systems designed for first-in, first-out applications.

Pallet flow uses inclined rollers or wheels that allow pallets to travel from the loading position down towards the picking or unloading position.

The inclined rails allow pallets to automatically travel into a picking position when the front pallet is unloaded which provides high inventory rotation and high storage-density.

Watch the video below to learn more about how pallet flow systems work.

When is it Best to Use Push Back Rack?

Push back racks are last-in, first-out storage systems. Therefore, if the inventory you are storing is date-sensitive, push back racks will not be beneficial. Push back racks are also limited to 6 pallets deep, so if you need to store 7 or more pallets deep, push back will not be ideal for you.

Additionally, push back racking eliminates the need for separate loading and unloading aisles. Instead, it only requires one aisle for loading and unloading, allowing for higher density in your overall space compared to pallet flow rack. Because of this, push back racks are ideal for areas where space is limited, like cooler or freezers.

When is it Best to Use Pallet Flow Rack?

Unlike push back rack, pallet flow rack is a first-in, first-out gravity flow storage system. This makes it ideal for items that are date-sensitive because product rotation is more automatic.

If your space allows for an extra aisle and you’d like higher density within each bay, pallet flow may be right for you. Pallet flow racking can store up to 12 pallets deep. It offers higher density per bay versus push back because of the small amount of space used for carts in push back rack.

Braking systems or speed controllers are design elements that may be engineered into pallet flow systems to help pallets gently travel from one position to the other. This is beneficial for sensitive products, like glass or carbonated beverages, that need extra caution to ensure they aren’t damaged when they move from each pallet position.

Why Not Both?

Keep in mind that you’re not restricted to one or the other. There may be a location within your distribution center in which pallet flow racking is ideal, such as an area where perishable items are stored, as well as a location in which push back racking is ideal, such as your cooler or freezer area. That’s why it’s important to evaluate each area individually to produce the optimal overall storage and flow process that a material handling system can provide.

Need More Information?

If you think your operation will benefit from incorporating push back racks, this case study showcases how REB was able to maximize a company’s storage area and eliminate the need for storing pallets on the floor.

If you think your operation will benefit from incorporating pallet flow rack, this case study showcases how REB provided a solution to satisfy a beverage distributor’s high-volume, date-sensitive inventory while safeguarding that no inventory spoils.

Let’s Connect!

It’s important that your storage system design meets your inventory needs and accommodates your company’s growth. REB Storage Systems International is highly knowledgeable and experienced in designing and installing all types of material handling systems, including pallet flow and push back. As a systems integrator, we’ll work with you to provide a turnkey system. From design, products procurement, subcontractor management, installation, and permitting support, REB handles it all for you.

Fill out the ‘Submit Your Inquiry’ Form to get in touch with our industry experts, who can help answer questions regarding what system can benefit your inventory the best.

Share this post:

Submit Your Inquiry

Since 1962

REB has completed more than 100,000 projects in 15 countries (including all 50 states) for more than 20,000 customers across 50 industries, with 70% of customers as repeat buyers.

This is made possible by our team that has more than 300 years of industry experience designing and project managing material handling systems.

Learn more about REB's award winning service.