Designing Custom Warehouse Systems

Designing or redesigning a warehouse racking layout can greatly increase your productivity and storage capacity while reducing the cost of goods stored and picked. Every layout is unique, but the goal of every warehouse rack design is to achieve the greatest storage density while optimizing the flow of products. A well-thought-out design considers not only the current needs but also the future growth and changes in operations.

At REB Storage Systems International, we understand the impact that a warehouse design has on operations. Our experienced team of project designers create professionally designed solutions to increase productivity and storage capacity while reducing the cost of goods stored and picked.

We’ve put together this article to help you begin your warehouse design project. It explores essential strategies for creating a warehouse layout that maximizes space utilization and productivity. To contact the professionals at REB for further assistance, fill out our form or call us at (800) 252-5955.

Step-by-Step Guide on Designing a Warehouse

Step 1: Needs Assessment

The first step to designing an optimal material handling system layout is to identify the specific needs of the distribution operation that will drive the design. Because no two distribution operations are exactly the same, understanding the specific needs of your operation helps in designing a layout that can adequately support these functions. Analyze the type(s) of inventory, the volume of goods, the frequency of shipments, handling requirements, inventory turnover, peak storage needs, and seasonal variations. Customizing the layout to fit these needs ensures the warehouse can handle these demands efficiently.

For example, gaining a thorough understanding of the characteristics of your inventory and product flow will help determine what type of material handling system is best. This includes the shelf lives and throughput rates of the items you plan to store. For items with expiration dates, a first-in, first-out rack system is ideal. Drive-in/through racking systems are ideal for products with longer life spans because they offer low selectivity. Selective racking systems are common in warehouses with continuous product circulation because it offers high selectivity.

Additionally, consider future growth projections to ensure the warehouse can adapt to changing needs.

Step 2: Space Analysis

Evaluate the amount of space able to be allocated to each distribution function. This is based on several factors including inventory types, volumes, turnover rates, and material handling practices. For example, aisle widths and system height play an important role in determining the density and selectivity your material handling system achieves. A key factor in determining aisle widths and system height is the type of picking practices used. If you are accessing products with a lift truck, the size of the truck will determine how narrow your aisles can be. This will also factor into how high you can build the system, since lift trucks will need to access the highest level of the system. This should be factored in with the amount of products that need to be stored to gain an understanding of how much space you’ll need for storage.

Step 3: Site Selection

Choose a location based on your needs assessment and space analysis. Additionally, logistical efficiency, proximity to transport links, and labor availability should be considered.

It’s important to do a rough layout of each facility that you’re considering to see if it can accommodate your needs. This case study demonstrates how taking this step can avoid contracting with a building that is not optimal.

Step 4: Design Phase

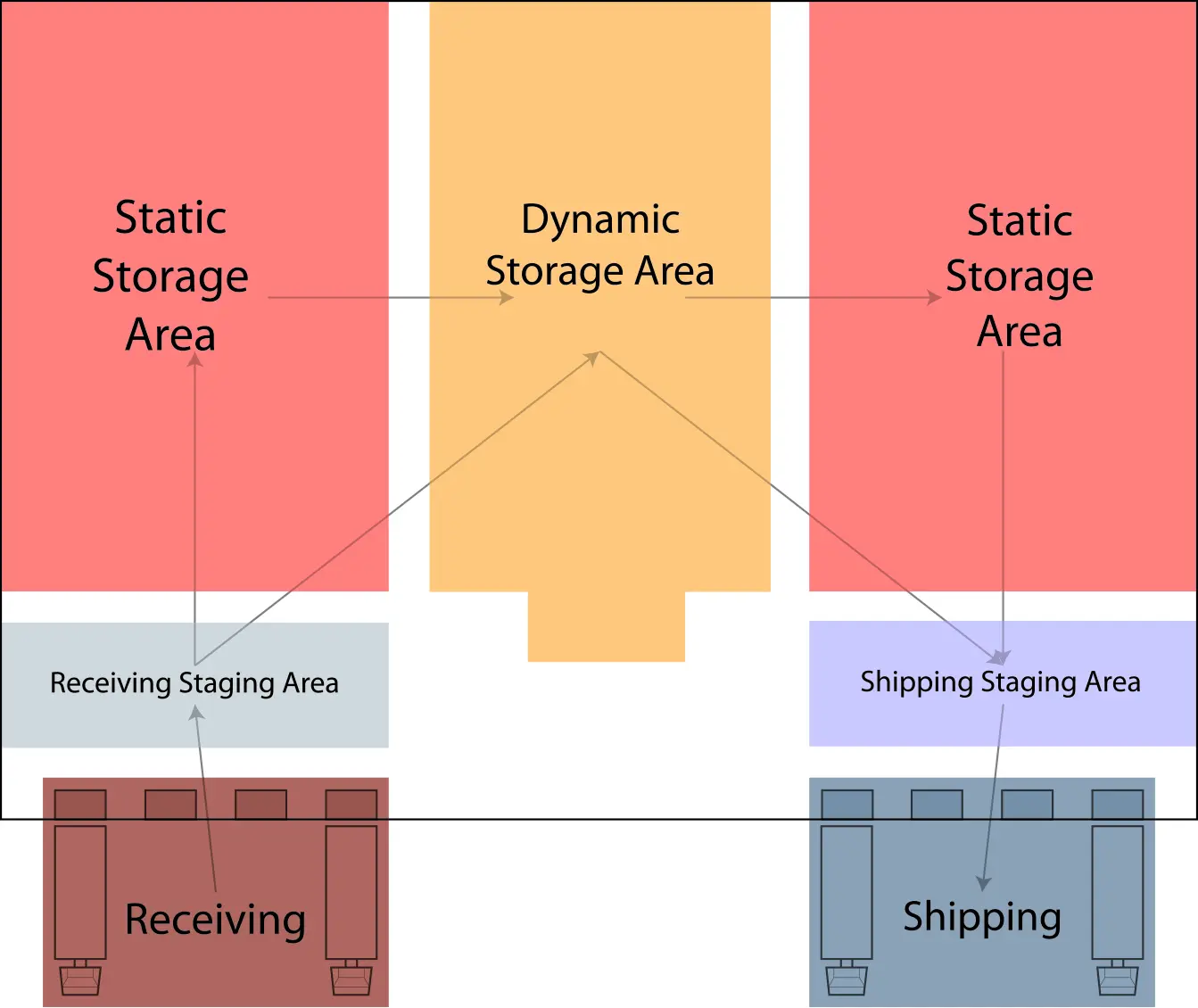

Efficient workflows are at the heart of productive warehouse operations. Develop a detailed warehouse layout that facilitates a logical flow of goods from receiving to storage and then to shipping, minimizing the distance and time required for these transitions. Consider the placement of docks, storage areas, and picking stations to reduce movement and improve the speed of operations.

When designing an existing warehouse, you should first survey and take measurements of the basic features of your space. Make note of any stationary features (columns, overhead doors, etc.) that you will need to work around. Take into account the location of items, such as dock doors, to get an overall idea of how your storage system will be set up.

To make the most out of the available warehouse space, consider the layout and type of storage systems. High-density storage solutions, like double-deep selective pallet racking, can dramatically increase your storage capacity. Utilizing vertical space with taller storage units and appropriate material handling equipment, like forklifts or stackers, can also expand your storage capabilities. Carefully plan the layout to minimize wasted space and ensure easy access to stored goods, facilitating quicker picking and stocking processes.

If you have multiple SKUs, you should determine the best location for each. For example, items that have quick turnaround times should be placed as close to shipping lanes as possible. This will reduce travel times and move a higher number of products faster, resulting in increased productivity and efficiency. Additionally, it’s often beneficial to place items that are typically picked together in close proximity.

Step 5: Technology Integration

During the design process, decide on the technology and automation systems that will enhance warehouse operational efficiency and accuracy. These can include warehouse management software (WMS), automated storage and retrieval systems (AS/RS), conveyors, and material handling equipment. These technologies reduce manual labor, improve inventory accuracy, and speed up processing times. Planning for technology integration in the warehouse design phase can future-proof the facility and ensure a high return on investment.

Step 6: Incorporate Flexibility and Scalability

The ability to adapt to change is a key feature of a well-designed warehouse. As businesses grow and change, the warehouse layout must be able to evolve accordingly. Designing for scalability ensures that the warehouse can accommodate future growth, new product lines, or changes in inventory levels without requiring a complete overhaul.

A cost-effective option to accommodate growth projections is to design the material handling system in multiple phases. This allows for part of the material handling system to be built, with designs for expansion phases taken into account.

Inventory increase projections should be factored into the design to avoid the need to move operations to a new building in the future. This can be factored into the design in several ways. One example is designing the material handling system so that it can be expanded vertically when needed. This case study demonstrates how a pick module can be designed so that a catwalk level can be added in the future. If a catwalk is not a viable option, certain types of shelving can be designed so that it can be spliced in order to add additional height in the future, read this case study to better understand the splicing method.

A material handling system design can also accommodate growth by planning for decreasing the existing footprint of the system and subsequently adding on to it. For example, selective rack with standard aisle widths can be reconfigured to have very narrow aisle widths. This will decrease the footprint of the selective rack system, allowing for additional rows of selective rack to be installed. This article explains the differences and considerations of standard aisles and very narrow aisles.

Step 7: Safety and Regulatory Compliance

Warehouse safety and ergonomics are paramount to designing. Ensure that aisles are wide enough to accommodate equipment and personnel safely, and that storage systems are stable and accessible. Ergonomic considerations, like adjustable picking stations and anti-fatigue matting, can reduce the risk of workplace injuries.

It’s important that your design adheres to all code requirements applicable to your location, commodity classification, material handling system type, and all others. Organizations such as MHI and the National Fire Protection Association (NFPA) have developed codes aimed at safety for warehouses, along with specific requirements put forth at the local and state levels. For this, a life safety evaluation or high pile storage report should be conducted by a professional as part of the design phase. These are assessments of codes that need to be adhered to within the warehouse design, such as egress aisles and fire alarm and sprinkler system requirements.

Step 8: Budget Planning

Once the design is finalized, develop a budget that covers installation, material, and labor costs. To achieve the most cost-effective system, it’s best to review several quotes for all materials and components. In addition to cost, lead time and product and service quality should be considered when choosing a supplier.

The budget should be regularly reviewed to ensure that the project is within budget. Because these are complex projects with many moving parts, it’s best to include a contingency fund within the budget for unexpected expenses.

Step 9: Implementation

Once the design is finalized and approved, begin the installation process. Carefully manage the project to keep it on schedule and within budget.

Step 10: Testing, Training, and Launch

Before full-scale operation, test the warehouse systems and train staff on new procedures and technologies. This phase helps in identifying and rectifying any issues. After ensuring everything is in place and functioning correctly, commence full operations. Monitor performance closely to identify areas for improvement.

Choose a Professional Design Team for Your Efficient Warehouse System Design

Your warehouse racking layout is critical to the workflow and the output of your facility. A proper design will make it easy to store, navigate, and locate products while giving you more space in your warehouse.

REB project designers take into account the layout of your space, the characteristics of your inventory, and the material handling equipment that your team uses. Clearly defining these requirements allows REB to develop the ideal solution as well as provide alternative solutions based on your budget and time frame. No matter what the needs of your space, we can create a professionally designed solution that will help you manage your inventory.

For more information on how to optimize your warehouse racking layout, fill in the contact form or call (800) 252-5955.

Share this post:

Submit Your Inquiry

Since 1962

REB has completed more than 100,000 projects in 15 countries (including all 50 states) for more than 20,000 customers across 50 industries, with 70% of customers as repeat buyers.

This is made possible by our team that has more than 300 years of industry experience designing and project managing material handling systems.

Learn more about REB's award winning service.